dust is accumulated in the chamber. It is important to clean mesh screen.

Use a soft brush or a vacuum cleaner to remove dust from the mesh screen.

In case of severe clogged mesh screen do the following.

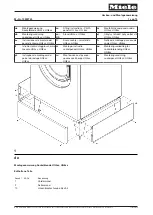

1. Open the chamber.

2. Remove two bolts (3)

3. Take out the baffler (2).

4. Clean the mesh screen (1).

5. Put the baffler back in the chamber.

6. Fix the baffler with the screws.

6.3

Clogged chamber

The chamber optical sensor provides accurate process of operation. The

new batch won’t be started until the previous batch is evacuated from the

chamber, thus the possibility of clogged chamber is minimal. However,

in case of lack of voltage in the mains, or using Emergency stop button

during the operation, or other reasons, the chamber may get clogged with

popcorn. In such case do the following:

1. DO NOT PANIC!

2. Unplug the machine from the mains.

3. DO NOT open the chamber, DO NOT use fire extinguisher! The

machine is made of stainless steel, as long as chamber door is closed,

popcorn may smolder and smoke, but won’t get fire.

4. Wait until the machine cools down (may take few hours).

5. Open the chamber and clean inside.

16