GENISYS AL-900

Dock Leveler Owner’s Manual

10

Publication:

AMEN00044 2017-01-27

MAINTENANCE

ALWAYS read and obey these instructions to prevent

personal injury.

• Post safety warnings and barricade work area,

at dock level and at ground level, to prevent

unauthorized use of the dock position before

maintenance has been completed.

• Make sure to install the maintenance support

strut before proceeding with any repair work.

SUGGESTED LEVELER MAINTENANCE

NOTE:

Follow maintenance procedures below as outlined.

Include the specific steps for your leveler model.

NOTE:

Your local Rite-Hite representative provides a

Planned Maintenance Program (P.M.P.) which can

be fitted to your specific operation. Call your local

representative

DAILY

1. Remove debris on and around leveler. Be sure the

hinge section of the lip and the platform is clean

2 Check unit for proper operation

90 Days

1. Perform all Daily Maintenance.

2 Clean pit

3. Inspect lip out mechanism (pins, lip crank, links, chains

and shackles). Replace if worn.

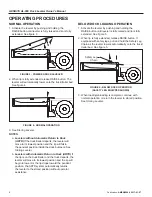

4 Lubricate the leveler with the proper lubricants See

figure 10.

NOTE:

Items that use Anti-Seize lubricant only require

lubrication every 360 Days

5. Inspect all weather seals (if installed) and replace if

worn or damaged

6. Inspect dock bumpers. Four inches (4”) of bumper

protection is required. Worn, torn, loose or missing

bumpers must be replaced

7 Check conditions of concrete, angles and welds

Repair or replace if necessary

8. Inspect structure, hinge pins, clevis pins and cotter

pins for abnormal wear

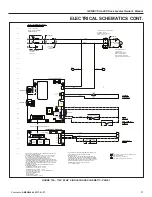

9. Inspect all conduit boxes, control boxes and electrical

connections for damage Repair or replace if worn or

damaged

NOTE:

If control box has evidence of condensation

a Inspect conduit Conduit should be routed to enter

through the bottom or side of the enclosure. A drip

leg may be needed if the conduit is filling with water.

b Inspect the seal on the cover of the enclosure The

seal should be securely adhered to the cover with

no signs of peeling or bubbling Repair or replace if

worn or damaged

c. For non-metalic enclosures, breather vent part

number 122130 may be installed. The vent is NEMA

4X and will not change the enviromental rating of

the control box

10. With the leveler supported by the maintenance strut,

inspect the air tower for damage Replace if worn or

damaged

11. Check Air Tower Tub placement in leveler frame is

correct. Pit floor must be clear of obstructions where

plastic tub is located Make certain tub hold down

chain is snug – no slack. See figure 11.

360 Days

1. Perform Daily and 90-Day Maintenance.

2 Check and tighten control box mounting hardware

Содержание Genisys AL-900

Страница 2: ...GENISYS AL 900 Dock Leveler Owner s Manual 2 Publication AMEN00044 2017 01 27 ...

Страница 21: ...GENISYS AL 900 Dock Leveler Owner s Manual Publication AMEN00044 2017 01 27 21 NOTES ...

Страница 27: ...GENISYS AL 900 Dock Leveler Owner s Manual Publication AMEN00044 2017 01 27 27 NOTES ...