19

ADJUSTING THE RIP FENCE FOR DRIFT

The 10-324TG Bandsaw can be adjusted to eliminate

‘drift’ - bringing the fence back to being parallel to the

blade - by two methods. To adjust the fence for drift:

Method 1. Loosen the two Hex Screws (#10F) which

hold the Rip Fence (#1F) to the Fence Carrier (#6F).

Adjust the fence so that is parallel to the blade/miter

gauge slots, then re-tighten the hex screws.

Method 2. Loosen the Fence Rail Nuts (#15F, Fig. 32

C) so that the fence rail can be adjusted in or out from

the table edge. This will position the fence left or right,

as needed, to align it parallel to the blade and miter

saw slots in the table. Once the fence is set,

tighten

the fasteners. Fig. 32, A.

ADJUSTMENTS

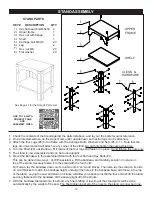

FIGURE 32

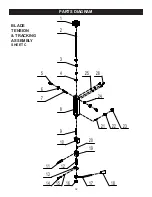

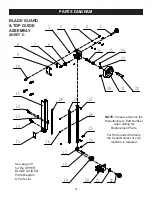

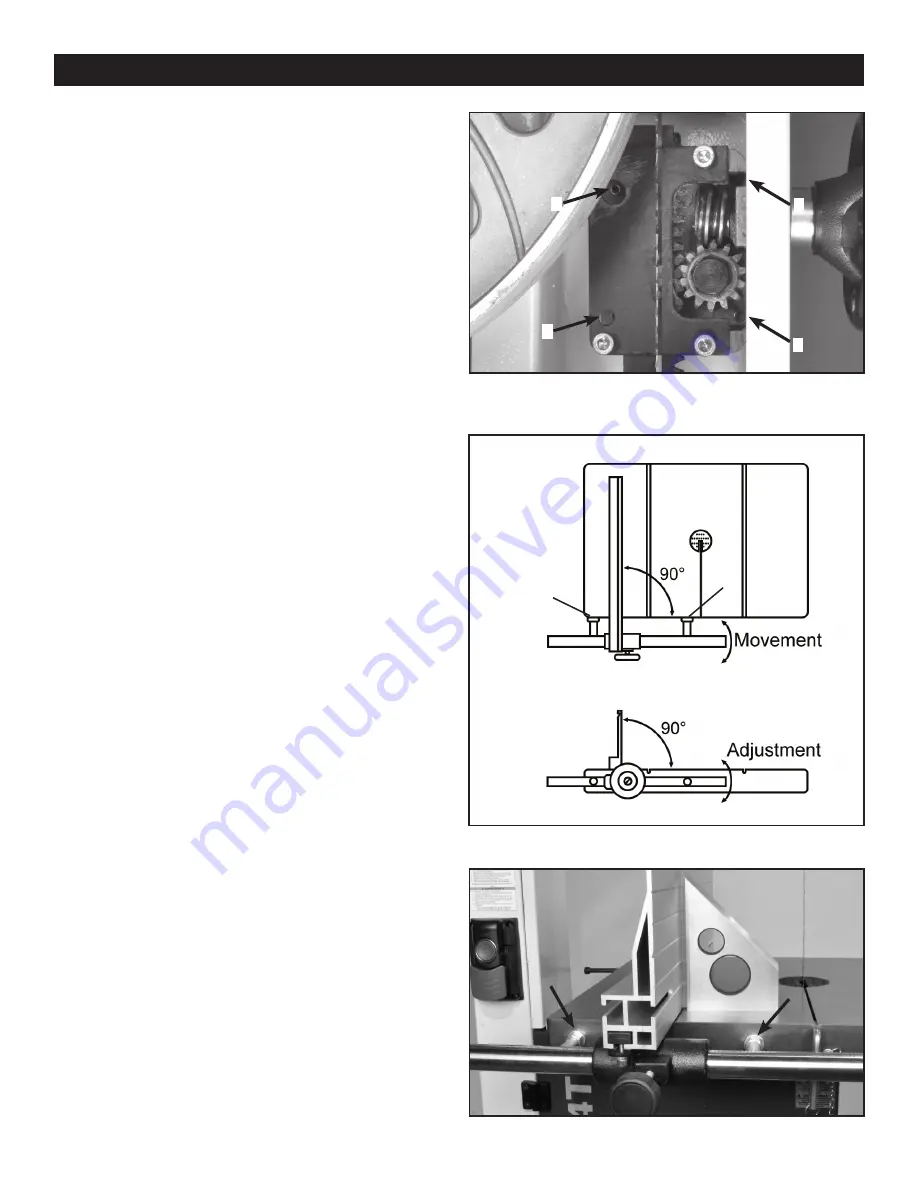

ADJUSTING THE BLADE GUARD - continued

3. Open the top door and lower the blade guard

all the way down to the table to access the Guide

Bracket block. Fig. 31.

4. Loosen the four Hex Bolts (C, Fig. 30) located at

the rear of the top frame. This will allow the guide post

to be shifted/angled a bit left or right to correct any

positioning issues.

5. There are also four Set Screws (Fig. 31) set in the

rear of the guide bracket near the corners. If the guard

post needs to be angled slightly towards the front or

back of the table, or even twisted on an angle, make

the adjustment with these screws.

- Advancing the top two set screws will angle the

post towards the rear of the table.

- Advancing the bottom two set screws will angle

the post towards the front of the table.

- Setting the two left or right screws will angle the

post to the right or left.

6. When the post is adjusted vertical, tighten the four

hex bolts that were loosened in step 4.

FIGURE 31

ADJUSTING THE FENCE 90° TO THE TABLE

Check that the fence is 90 degrees to the table using

a square. If adjustments are required,

loosen the

Fence Rail Nuts (#15F, Fig. 32, C) and

raise or lower

either side of the fence’s Guide Rail until the fence is

90 degree to the table. Once set at 90 degrees, fully

tighten the fence bar nuts. Fig. 32, B & 33.

See page 12 for the guide rail installation process.

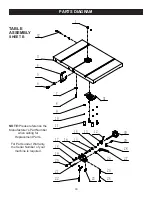

FIGURE 33

90°

B

A

B

C

C

1

2

3

4

Содержание 10-324TG

Страница 43: ...43 OPERATION...