11

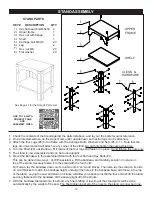

TABLE ASSEMBLY

1. Remove the Table Leveling Pin (Part #4B) from the

front of the table. This metal pin keeps the two sides

of the table level at the slot area. Fig. 1.

2. Mount the table in place on the trunnion with the

assistance of another person. The table is heavy!

Do this from the rear of the machine, so that it is

easier to fit the pre-installed blade through the slot in

the table.

3. Attach the table to the trunnion with the four Hex

Socket Cap Screws, Spring Washers and Washers

(Parts #11B, 10B, 9B). Install two bolts to the right of

the blade, hand tightened only. Fig. 2. Then tip the

table to 45 degrees and install the two bolts to the left

of the blade. Fig. 3.

DO NOT

fully tighten the bolts at

this time. Return the table to the horizontal position.

NOTE:

Before finally secured in position, the table can

be slightly moved, left and right. Check to make sure

that the table’s miter gauge slot is parallel to the side

of the saw blade. This will provide a true cut when

ripping stock. Set a thin metal ruler against the side

of the saw blade. Make sure that it is not touching

the saw’s teeth, which can angle the ruler. Measure

the distance from one end of the ruler to the miter

gauge slot. FIG. 4. Then measure the same distance

from the other end of the ruler to the miter gauge slot.

Compare these two measurements and angle the

table as necessary until the distances are the same.

4. Once the table is aligned parallel to blade, tighten

all four of the installed bolts to secure the table in

place.

FIGURE 1

ASSEMBLY

FIGURE 2

THE MACHINE MUST NOT BE

PLUGGED IN AND THE POWER SWITCH MUST BE IN

THE OFF POSITION UNTIL ASSEMBLY IS COMPLETE.

FIGURE 4

FIGURE 3

NOTE:

Parts referenced throughout the manual

refer to the different sheets and key numbers of the

Parts Diagrams and Parts Lists on pages 28 to 40.

Example: (#7A) refers to Part #7 on Sheet A.

INSTALL THE 90° TABLE STOP

Thread the Hex Bolt (#8B) and Nut (#7B) to the

bottom of the table in the pre-bored and tapped hole.

See Fig. 1

2, page 13. Setting the table to 90° to the

blade will be done later on pages 13 & 14.

Содержание 10-324TG

Страница 43: ...43 OPERATION...