12

Removing the Flapper Valves

Note: We recommend you remove and replace one

flapper valve at a time. This will help to

simplify the repair process and orient the

flapper valve correctly on the valve plate.

1.

If you are replacing a flapper valve on the

top side of the valve plate (side facing the

head), remove the flapper valve screw (1)

with a 1/4" hex socket, lift off the valve keeper

strip (2), lift off the valve restraint (3), and lift

off the flapper valve (4).

2.

Remove any debris from the valve plate with

a damp, lint free cloth. (Soaps and

detergeants should not be used due to the

potential for corrosion from soap residue.)

3.

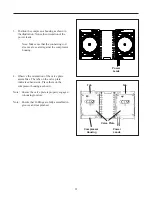

Place the valve plate on the compressor

housing and orient it as illustrated. Note the

orientation of the valve ports.

4.

Orient a new flapper valve (1) over Port 1.

Observe the location of the notches (2) at the

end of the flapper valve.

2669-6

Opposite Lead Side

2

2

1

Port 2

Port 1

1

2

3

4

Opposite Lead Side