2902936

8

GB

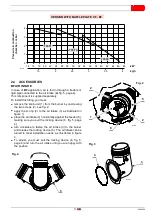

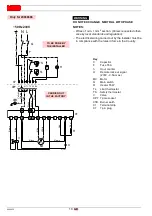

Depressurised systems have a negative fuel pressure (depression) on intake to the burner.

Usually the tank is lower than the burner.

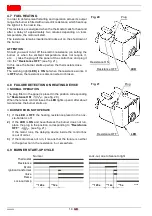

In the systems in figs. 13 and 14, the table shows the maximum indicated lengths for the supply line, depend-

ing on the difference in level, length and the diameter of the oil pipes.

PRIMING PUMP

On the systems in fig. 13 and 14 start the burner and wait for the priming.

Should lock-out occur prior to the arrival of the fuel, await at least 20 seconds before repeating the operation.

In two pipe vacuum systems (fig. 14) the return line should terminate within the oil tank at the same level as

the suction line. In this case a non-return valve is not required.

Should however the return line arrive over the fuel level, a non-return valve is required.

This solution however is less safe than previous one, due to the possibility of leakage of the valve.

DEPRESSURISED SYSTEMS

(fig. 13 and 14)

H

m

a

x

.

4

m

m

a

x

.

4

m

H

H

H

D7008

●

●

H

meters

L meters

I. D.

8 mm

I. D.

10 mm

0

0.5

1

1.5

2

3

3.5

35

30

25

20

15

8

6

100

100

100

90

70

30

20

●

ONLY FOR ITALY:

Automatic shut-off device as per Ministry of Internal Affairs’ regulation no. 73

dated 7/29/71.

The installer must ensure that the supply depression is not above 0.4 bar

(30 cm Hg).

Above that level, gas leaks out from the fuel.

The pipes must all be perfectly sealed.

H = difference of level; L = max. length of the suction line;

I. D. = internal diameter of the oil pipes.

ONE PIPE SYSTEM

TWO PIPE SYSTEM

Fig. 13

Fig. 14