15

2902936

GB

5.

MAINTENANCE

The burner requires periodic maintenance carried out by a qualified and authorised technician in conformity

with legislation and local standards.

Periodic maintenance is essential for the reliability of the burner, avoiding the excessive consumption of fuel

and consequent pollution.

Before carrying out any cleaning or control always first switch off the electrical supply to the

burner acting on the main switch of the system.

THE BASIC CHECKS ARE:

➤

Check that there are no obstructions or bends in the supply or return oil pipes, in the air intake pipes and the

combustion product discharge tubes.

➤

Clean the filter in the oil suction line and in the pump.

➤

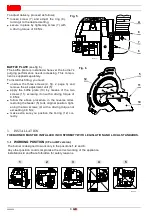

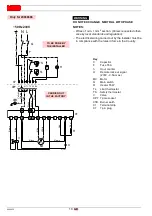

Clean the

flame sensor

(see fig. 16).

➤

Check for correct fuel consumption.

➤

Replace the nozzle (4, fig. 17) and check the correct position of electrodes (fig. 18).

➤

Clean the combustion head in the fuel exit area.

➤

Leave the burner working without interruptions for 10 min. and set rightly all the components stated in this

manual. Then carry out a combustion check verifying:

●

Smoke temperature at the chimney;

●

Content of CO

2

( % );

●

Content of CO (ppm);

●

Smoke value according to opacity smokes index according to Bacharach scale.

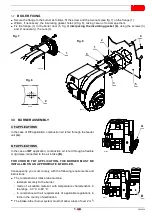

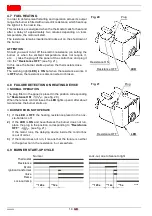

5.1

ACCESS TO THE FAN,

(see fig. 22)

IMPORTANT

➤

Perform maintenance work only when strictly neces-

sary, taking great care not to damage or unbalance

the fan during cleaning.

➤

Take careful note of the original position before

beginning any of these operations.

Proceed as follows:

➤

Unscrew the three screws (1) and remove the air adjust-

ment unit (2). At this point, you can clean the fan: vacuum

up any impurities, taking care they do not enter the air cir-

cuit.

➤

Refit following the above procedure in the reverse order,

restoring the air adjustment unit (2) to its original position

and being extra careful to ensure that the O-ring (12, fig.

6, page 3) is positioned correctly.

➤

Tighten the three screws (1) with a driving torque not

exceeding 0.8 Nm.

D7004

1

1

1

2

3

Fig. 22