28

PRE-INSTALLATION CHECKS

The leaf must be fixed firmily on the hinges to the pillars, must not be flexible during the

movement and must move without frictions.

Before the installation of KING 24V, verify all dimensions etc.

There’s no need for any modification, if the gate is like that shown in Fig. 1.

Gate features must be uniformed with the standards and laws in force.

The gate

can be automated only if it is in a good condition and its conditions comply with the EN

12604 norm.

- The gate leaf does not have to have a pedestrian opening. In the opposite case it

is necessary to take the appropriate steps, in accordance with EN 12453 norm (for

instance; by preventing the operation of the motor when the pedestrian opening is

opened, by installing a safety microswitch connected with the control panel).

- No mechanical stop shall be on top of the gate, since mechanical stops are not safe

enough.

Parts to install meeting the EN 12453 standard

COMMAND TYPE

USE OF THE SHUTTER

Skilled persons

(out of public

area*)

Skilled persons

(public area)

Unrestricted

use

with manned operation

A

B

non possibile

with visible impulses

(e.g. sensor)

C or E

C or E

C and D, or E

with not visible impulses

(e.g. remote control

device)

C or E

C and D, or E

C and D, or E

automatic

C and D, or E

C and D, or E

C and D, or E

* a typical example are those shutters which do not have access to any public way

A: Command button with manned operation (that is, operating as long as activated),

like code ACG2013

B: Key selector with manned operation, like code ACG1010

C: Adjustable power of the motor

D: Safety strips and/or other safety devices to keep thrust force within the limits of

EN12453 regulation - Appendix A.

E: Photocells, like code ACG8026 (To apply every 60÷70cm for all the height of the

column of the gate up to a maximum of 2,5m - EN 12445 point 7.3.2.1)

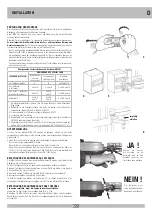

EMERGENCY RELEASE

To move the gate manually it is necessary to release the operator inserting the special

key and turning it 2 times in the anti-clockwise sense (Fig. 3).

In order to carry out the manual operation of the gate leaf the followings must be checked:

- That the gate is endowed with appropriate handles;

- That these appropriate handles are placed so to avoid safety risks for the operator;

- That the physical effort necessary to move the gate leaf should not be higher than 225

N, for doors/gates for private dwellings, and, 390N for doors/gates for commercial and

industrial sites ( values indicated in 5.3.5 of the EN 12453 norm).

FIXING THE ACTUATOR ATTACHMENT TO THE COLUMN

To obtain a correct movement of the leaf gate it is necessary to respect the measures.

In case an iron pillar is available, weld the bracket straight to it.

In case you need to fix the bracket onto a concrete pillar, use the fixing plate as shown

in picture 4, to be fastened with 4 Fischer screws of Ø 8 mm.

In the case you have a wall parallel with the open gate, you must provide a niche in which

to place the operator.

FIXING THE ACTUATOR ATTACHMENT TO THE GATE

Before inserting the pin into the gate attachment, grease thoroughly.

Weld the base at the right height (Fig. 6, 7).

Fix the KING 24V and try several times to open and to close the gate, controlling that the

operator does not touch the moving gate.

INSTALLATION

G

B

3

4

5

6

Grease

thoroughly

Be sure to tighten the bolt

that holds the bracket to

the operator so that it can

rotate freely.

YES !

The operator must not

vary its height during the

movement.

NO !