Operation and Maintenance Manual – Steam sterilizers mod. Sterilix 2 Plus & Vacuum Plus & Star & Star Fast

Rev. 09 of 18-04-02 - E:\Documenti1\Manuali superati non in uso\Vacuum Star GB-R09.doc

Page 28 of 42

10.1 Troubleshooting: Solutions / Remedies

01- tPt

Repeat the sterilizing process or contact the after-sales service center.

02- rEt

Wait until the power supply returns. Check the socket and replace it if necessary.

Eliminate any reductions / multiple sockets to which the machine may have been

connected. Keep electronic machines well away from the appliance as they may create

disturbance (e.g. ultrasound equipment, microwaves, cellular telephones or other

equipment that emit radio frequencies). Do not touch the machine for 3 minutes wih

the switch on.

Once the 3 minutes have elapsed, the machine will make a double acoustic signal.

Leave the main switch on. Make sure that the pressure gauge needle is on the “0” mark

(zero). Open the door and keep the “DEDUCTION” key depressed for at least 5

seconds, then release it. The machine will reset automatically now to begin a new

sterilizing cycle.

03- dor

Wait until the message stops flashing and then open the door.

04- SLP

Press any key to re-activate the functions if the machine must be used again, otherwise

switch off the machine.

05- PtL

Repeat the sterilizing process if necessary. Contact the after-sales service center if the

message appears again.

06- btP

Open the machine and repeat the sterilizing process. Contact the after-sales service

center if the message appears again.

07- PrS

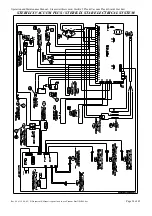

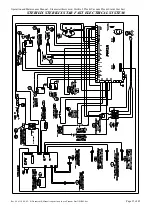

- there may be a short-circuit in the N.O. solenoid valve coil: replace the coil.

- jamming or foreign bodies under the solenoid valve seals.

Clean or replace the part. NOTE: this operation must only be carried out by After-sales

Service staff.

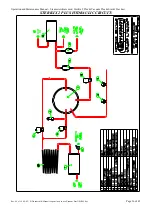

- water fails to enter the chamber even though the level gauge gives the green signal.

- the internal temperature governor type PT 100 is badly calibrated. Regulate it by

means of the internal TRIMMER.

Check and calibrate the probe: NOTE: this operation must only be carried out by After-

sales Service staff.

08- otr

Check and calibrate temperature probe type PT 100: NOTE: this operation must only be

carried out by After-sales Service staff.

09- Lot

Autoclave on in a cold room: heat the room or check to make sure that the probe

operates correctly.

10- ntP

- The wire of the heating element has probably detached.

- Burnt-out heating element.

- The connection does not conform to the heating element.

- Faulty TRIAC: check the connections with a multimeter and replace the part if

necessary. Use a genuine spare part and take great care to make the connections in the

correct way. NOTE: this operation must only be carried out by After-sales Service

staff.

11- HIt

Temperature too high:

- Check and calibrate temperature probe type PT 100: NOTE: this operation must only

be carried out by After-sales Service staff.

- Faulty TRIAC: check the connections with a multimeter and replace the part if

necessary. Use a genuine spare part and take great care to make the connections in the

correct way.

A wire of temperature probe type PT 100 has broken: check the connection terminal

and replace the probe with a genuine spare if necessary.

NOTE: both these operations must only be carried out by After-sales Service staff.