© RESOL 11294 flo

wsol_d_d_he

.monen.ind

d

FlowSol D / D HE

7 |

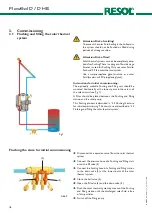

When you did not carry out the steps described in chapter

3.2, please carry out steps 1 to 5 of chapter 3.2 before you

carry out the following steps:

Î

Turn the ball valves in flow (1) and in return (2) with

an open-ended spanner (wrench width 14) to a 45°

position. The non-return valves in the ball valves are

now open (fig. 4).

Î

Flush the solar thermal system using the flushing and

filling station for at least 15 minutes to remove all air

from the system. During this process, the solar pump

may run in manual mode.

Î

During flushing, bleed the solar thermal system several

times at the AirStopp until the discharged solar fluid is

free of air bubbles.

Î

Connect the expansion vessel to the solar thermal

system

Î

Close the drain valve (5) of the flushing and filling unit

with the filling pump running and increase the system

pressure to approx. 5 bar. The system pressure can be

read from the manometer

Î

Close the fill valve (3) and switch off the pump of the

flushing and filling station as well as the solar pump.

Î

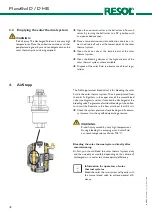

Check the manometer to see whether the system pres-

sure reduces (approx. 15 minutes) and eliminate leaks

where necessary.

Î

Set the operating pressure of the solar thermal system

(approx. 0.5 bar higher than the inlet pressure of the

expansion vessel) by opening the drain valve (5).

Î

Close the drain valve (5) and open the ball valve (4).

Î

Remove the hoses of the flushing and filling station and

screw the caps onto the fill and drain valves.

Î

Put the non-return valves in flow and return in operating

position by putting them in a vertical position (fig. 4)

using an open-ended spanner (wrench width 14).

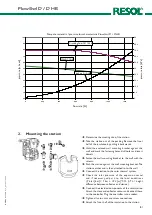

ball valve: 45°

non-return valve

not operating

flow-through in both

directions

ball valve: 90°

ball valve closed, no

flow-through

ball valve: 0°

non-return valve

in operation, flow-

through only in flow

direction

fig.3

fig.4

1

2

Flushing and filling the solar thermal

system