© RESOL 11294 flo

wsol_d_d_he

.monen.ind

d

FlowSol D / D HE

3 |

Scope of delivery:

1 x pump station

FlowSol

D / D HE

with integrated

DeltaSol

®

D / D HE

controller

1 x collector sensor FKP6

1 x store sensor FRP6

1 x wall mounting bracket

1 x accessory bag

2 x screw and dowl

2 x strain reflief

1. Pump station with integrated controller

• Integrated controller

DeltaSol

®

D / D HE

• Outstanding design

• Ultra fast and precise digital sensors for tem-

perature, pressure and flow rate

• Safety assembly with safety valve and mano-

meter

• High-quality casing for reduced heat losses

Pump stations offer solutions for the efficient use of a

system through harmonized components. The new station

RESOL

FlowSol D / D HE

is characterized by the digital

sensors, which communicate with the controller via the

RESOL VBus

®

and which ensure the precise measurement

of temperature, pressure and flow rate. The enhanced status

and error diagnostic system allows for easy and intuitive

display of system states. Due to pictograms and graphic

balances, it can be easily and quicklyfound out whether the

system runs faultlessly or if there is an error.

As is the case with all other RESOL pump stations, the

shapely design of the

FlowSol D / D HE

plays an im-

portant role. The integrated controller has a full graphic

display, which displays the system states and ensures easy

and intuitive menu navigation. The station is equipped with

important componants and safety assemblies for operating

the solar thermal system:

•

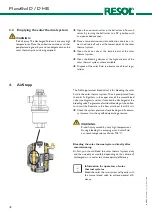

Ball valves in flow and return in combination with check

valves to prevent gravity circulation

•

Digital sensors for measuring temperature, pressure and

flow rate

•

AirStopp for manual bleeding of the solar thermal system

•

Manometer for displaying the system pressure

•

Safety valve to prevent inadmissible overpressure

•

High-efficiency pump (on

FlowSol D HE

only)

The installation and commissioning of the solar station as

well as the connection of electrical components requires

technical knowledge commensurate with a recognised

vocational qualification as a fitter for plumbing, heating and

air conditioning technology, or a profession requiring a com-

parable level of knowledge. The following must be observed

during installation and commissioning:

•

the relevant regional and national regulations

•

the accident prevention regulations of the trade asso-

ciation

•

the technical and safety instructions of these instructions

Safety instructions

Warning: Risk of scalding

There is a danger of steam emission with safety val-

ves. Therefore a discharge pipe must be connected

to the ¾“ internal thread of the safety assembly.

Please observe the enclosed instructions regarding

the safety valve when doing this.

Attention: Damage to property

The group of fittings must be installed with suffici-

ent spacing to the collectors because temperatures

in the vicinity of the collectors can be very high. An

intermediate vessel may be necessary for installa-

tion in the attic.

Attention: Damage to property

It is imperative that you make sure the EPDM

sealing elements of the solar station do not come

into contact with substances containing mineral oil.

Mineral oil products cause lasting damage to the

material, whereby its sealant properties are lost.

If necessary, ask the manufacturer whether the so-

lar fluid, fats or installation aids contain mineral oils.

We do not assume liability nor provide warranty

for damage to property resulting from sealants

damaged in this way.