6

Important Information about Safe Setup

◊

The units may only be set up and operated in rooms

where there is enough air for combustion and the ex-

pelled air is guided to the outside via an exhaust sys-

tem.

◊

Units dependent on air in the room may only be set

up in rooms or buildings from which air is suctioned

out by means of fans (such as ventilation or exhaust

systems) if:

1. Safety mechanisms prevent the units and the air

suctioning system(s) from operating simultane-

ously.

2. The expulsion of exhaust is monitored by special

safety devices.

3. The exhaust produced by the units is expelled by

means of the air suctioning system(s).

4. The design or dimensions of the system ensure

that no dangerous negative pressure can be pro-

duced.

◊

The units must be placed firmly on a suitable, non-

flammable surface outside of traffic zones, for exam-

ple, away from cranes.

◊

The units must be set up and operated in such a way

that people are not exposed to exhaust or radiant

heat and fires cannot occur.

◊

The units must be set up in such a way that they do

not cause any hazards or unreasonable annoyances,

e.g. tremors, vibrations or noise.

◊

The units must be set up and installed in such a way

that they are easily accessible for monitoring, repair

and maintenance work.

◊

Operating elements which can result in dangerous

operating conditions when used improperly must be

protected from unauthorised operation if they are

generally accessible.

◊

When attaching mixed air flaps (accessories), they

must be connected against the flow of air and ensure

a minimum cross-section for an adequate external

air rate.

◊

The units may not be set up or operated in rooms or

areas susceptible to fire or explosions.

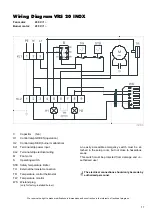

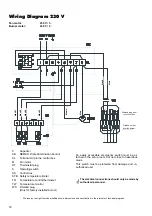

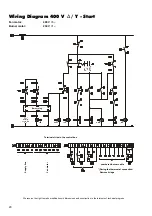

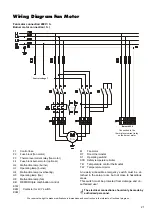

Power Supply

Prior to performing the electrical installation in line with

local requirements, check whether it is possible for even

a temporary power overload to cause an impermissible

undervoltage.

To connect the units, the line cross-sections are to be

placed in such a way that they do not caused the burner

voltage to lower to an impermissible level when the fan

is started.

Air Supply for Combustion

An adequate supply of air for combustion must be en-

sured by meeting the relevant building requirements.

Excerpts from the German fire ordinance:

(1) For furnaces with a total rated heat output of up to

35 kW that are dependent on the air in the room,

evidence of an adequate air supply for combustion

has been provided if the furnaces are set up in a

room that has:

1.

A minimum of one door to the outside or a win-

dow that can be opened (rooms with a connec-

tion to the outside) and a room capacity of at

least 4 m

3

per kW of total rated hear output or

2.

An opening leading to the outside with a cross-

section of at least 150 cm

2

or two openings

which are each 75 cm

2

or lines to the outside

with equivalent cross-sections for air flow.

(2) For furnaces with a total rated heat output of more

than 35 kW and less than 50 kW that are depend-

ent on the air in the room, evidence of an adequate

air supply for combustion has been provided if the

furnaces are set up in rooms that meet the require-

ments of Para. 1, No. 2.

(3) For furnaces with a total rated heat output of more

than 50 kW that are dependent on the air in the

room, evidence of an adequate air supply for com-

bustion has been provided if the furnaces are set up

in rooms that have an opening or a line leading to

the outside.

The cross-section of the opening must be at least

150 cm² plus and additional 2 cm²

for each kW of

rated heat output which is above 50 kW.

The lines’ cross-sections must have equivalent

measurements for air flow.

The required cross-section may not divided among

any more than 2 openings or lines.

(4) Combustion air openings and lines may not be

closed or blocked unless the safety mechanisms

can ensure that the furnace can only be operated

when the flap is closed.

The required cross-section may not be constricted

by the flap or the grille.

(5) As an exception to Paras. 1 to 3, for furnaces de-

pendent on air in the room, evidence of an ade-

quate air supply for combustion can be provided

other ways.

For example by:

A continuous line to the outside with a sufficient

cross-section that is attached to the burner or its lin-

ing. This must be adjusted to the suction capacity of

the burner and the line resistances (including the

protective air suction grille) so that combustion is

assured.