13

The unit does not start

1. Check the power supply

2. Check the fuses in the control box.

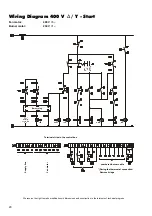

Only for units in the 400 V rotary current series.

3. Check the safety temperature limiter.

If the safety temperature limiter (STB) has been acti-

vated, the reason the unit overheated must be deter-

mined. The following are possible causes:

◊

The unit could not cool down because the

power supply was interrupted. Even short inter-

ruptions can activate the STB.

◊

The temperature of the air being blown out is

too high because the grilles have not been prop-

erly adjusted.

◊

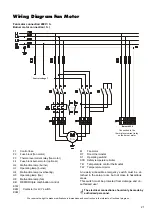

The fan was overloaded and the thermal over-

current relay of the 400 V series was activated

or the thermal contacts in the fan motor of the

230 V series were activated.

◊

The V-belt of the fan drive is loose or defective.

◊

Air intakes and outlets are blocked.

4. Check the operating and/or main switch.

5. Check the room thermostat setting.

The room thermostat must be set higher than the

room temperature.

6. Set the operating switch to “Lüften” (fan) or “

II

”.

If the air supply fan starts now, look for the problem

in the burner.

Troubleshooting

The unit was subjected to repeating testing during pro-

duction to ensure that it functions properly.

However, if you still experience functional problems,

please refer to the list below.

The burner does not start

◊

Check whether the fuel filter is dirty.

◊

Check whether the shut-off valve of the fuel filter is

open.

◊

Check that there is enough fuel in the fuel container.

◊

Check whether paraffin has accumulated in the heat-

ing oil.

This can occur at temperatures below 5 °C.

◊

Check oil lines for damage.

Leaks can cause air intake.

◊

Use suitable means to ensure that the safety tem-

perature limiter (STB) and the temperature monitor

(TW) are functioning properly.

◊

Check the sensors and capillary pipes of the TW and

STB for damage and ensure that the sensor has

been properly positioned.

◊

Check whether the burner malfunction control lamp

on the oil firing device is illuminated.

If so, release the relay by pressing the malfunction

button. The malfunction light goes out and the burner

tries to start. Keep in mind that some burners have a

delayed start due to the oil preheating process for

some units.

G

If, after the start phase, the burner switches off due

to a malfunction, you may only re-release it after

waiting 5 min. Additional releases are strictly pro-

hibited as there is a risk of explosion.

The air supply fan does not start

◊

Set the operating switch to “Lüften” (fan) or “

II

”.

The air supply fan should now start.

◊

Check that the fan and the fan drive are running

smoothly.

◊

Check the V-belt on the fan drive.

◊

Check the electric cord on the fan motor for damage.

◊

Check whether the capacity of the fan was ex-

ceeded.

The thermal overcurrent relay (400 V series) or the

thermal contacts (230 V series) in the fan motor

have been activated.

◊

Check the operating capacitor of the fan.

Only for the 230 V series.

◊

Check that the temperature control thermostat (TR)

is working properly.

G

Should the unit still not function properly after per-

forming these checks, please contact an author-

ised service centre.

G

Please carry out an electrical safety test after hav-

ing finished service on the unit.

G

For safety purposes, repair work on the electrical

components and the burner may only be per-

formed by authorised personnel.

G

An operation/use other than indicated in these in-

structions is prohibited!

In the case of non-compliance, we assume no li-

ability and our guarantee becomes null and void.

Service and Guarantee

For the guarantee to be valid, the customer must com-

pletely fill out the “guarantee certificate” enclosed with

all heating units and send it back to REMKO GmbH &

Co. KG in a timely manner after purchasing of the unit

and putting it into operation.

The units have undergone several tests to ensure

proper functioning at the factory. If there are still mal-

functions that cannot be fixed by the operator using the

troubleshooting instructions, please contact your dealer

or contract partner.