22

BA 90M-P140M-P160M(D) 0802/dfe

–

Cooling water outlet:

Must be free of backflow and open at all times. The hose must be connected such that any

vapour escaping at the start of the cooling process does not present a hazard.

–

For safety reasons, the cooler must be connected at all times

.

2.5

Electrical connections

The unit must be connected by a qualified electrician only.

1

Mains current and frequency must correspond to the information found on the rating plate.

2 Compare the value of the back-up fuse to the information in the electrical schematic in the electrical section of the

unit. Ensure that the power input corresponds to that listed on the rating plate.

3 All applicable guidelines and safety regulations shall be followed when connecting the unit to the mains.

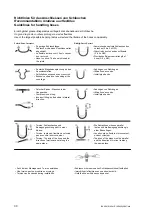

2.5.1 Interface cable and optional equipment (Fig. 1 and 2)

If the unit is equipped with an interface, its cable must be fed beneath the electrical housing door. When moving the

unit, ensure that the rollers do not roll over the cable.

2.6 Safety

equipment

In addition to the usual safety equipment, such as electrical overload protection of the pump motor, safety thermostat,

level monitor and filter, the unit is equipped with the following monitoring equipment to ensure safe and reliable

operation:

– Pressure

gauge:

In Model 90M, the displayed value corresponds to the pressure in the outlet hose.

In Models P140M and P160M(D), the pressure gauges show the pressure in the outlet hoses and the system pressure,

which is comprised of the pressure caused by the expansion of the water and the saturated vapour pressure.

– Pressure

relief

(P140M and P160M[D]): The RT50 control system provides pressure relief by automatically switching to

pressureless operation at temperatures below 80 °C. (This value can be decreased, depending on the value of the run-

out temperature programmed. See the RT50 Programming Instructions, Section P 4.3).

Additional pressure relief occurs when the unit is switched to

OFF

. This guarantees that the unit is free of pressure

after it is switched off, despite any backpressure in the drain.

– Bypass:

Prevents the pump from damage (running dry) due to e.g. a closed shut-off valve in the consumer circuit.

– Safety

valve

(P140M and P160M[D]):

Set pressure 10 bar

(

→

Service).

–

Operating under pressure:

In operation under pressure (above 80 °C), pressure is applied to the unit by opening the

filling valve periodically. The pressure in the unit thereby corresponds to at least that of the water mains.

2.7 Switching on

Open the vent valve at the consumer as well as the shut-off valve (when present).

After checking the consumer, connecting the hoses, establishing the electrical connections, and opening the shut-off

valves in the outlet and inlet, proceed as follows:

2.7.1

Switching on with the RT32 control system (Gefran 1200) (Fig. 3, Table 1)

Model 90M only: Switch the unit/pump on using the corresponding switch.

Once the unit has been switched on, the RT32 (Gefran 1200) will run a functional test for approximately 2 seconds.

During this test, all displays will blink. Once the test has been completely successfully, the actual value will appear in

the upper display field and the set-point value in the lower. The unit will now fill with water automatically. Ensure that

the pump’s direction of rotation corresponds to the arrow.

If the direction of rotation is incorrect, switch the phases on the unit’s plug.

Check for leaks in the temperature control circuit (unit, connection hoses, consumer, etc.).

Close the vent valve once water flows out of it regularly.

The unit will switch on again automatically after a power outage.

2.7.2 Setting elements

Enter the set-point value using the

Δ

and

∇

keys.

Fig. 1: Interface cable

Fig. 2: Plug connection (optional)

Содержание 90M

Страница 1: ...90M P140M P160M D Betriebsanleitung Instructions de service Operating Instructions ...

Страница 42: ...41 BA 90M P140M P160M D 0807 dfe Massblatt Dimensions 90M P140M P160M ...

Страница 43: ...42 BA 90M P140M P160M D 0807 dfe Massblatt Dimensions P160MD ...

Страница 44: ...44 BA 90M P140M P160M D 0807 dfe ...