17

15.2 THE CRANKSHAFT

.

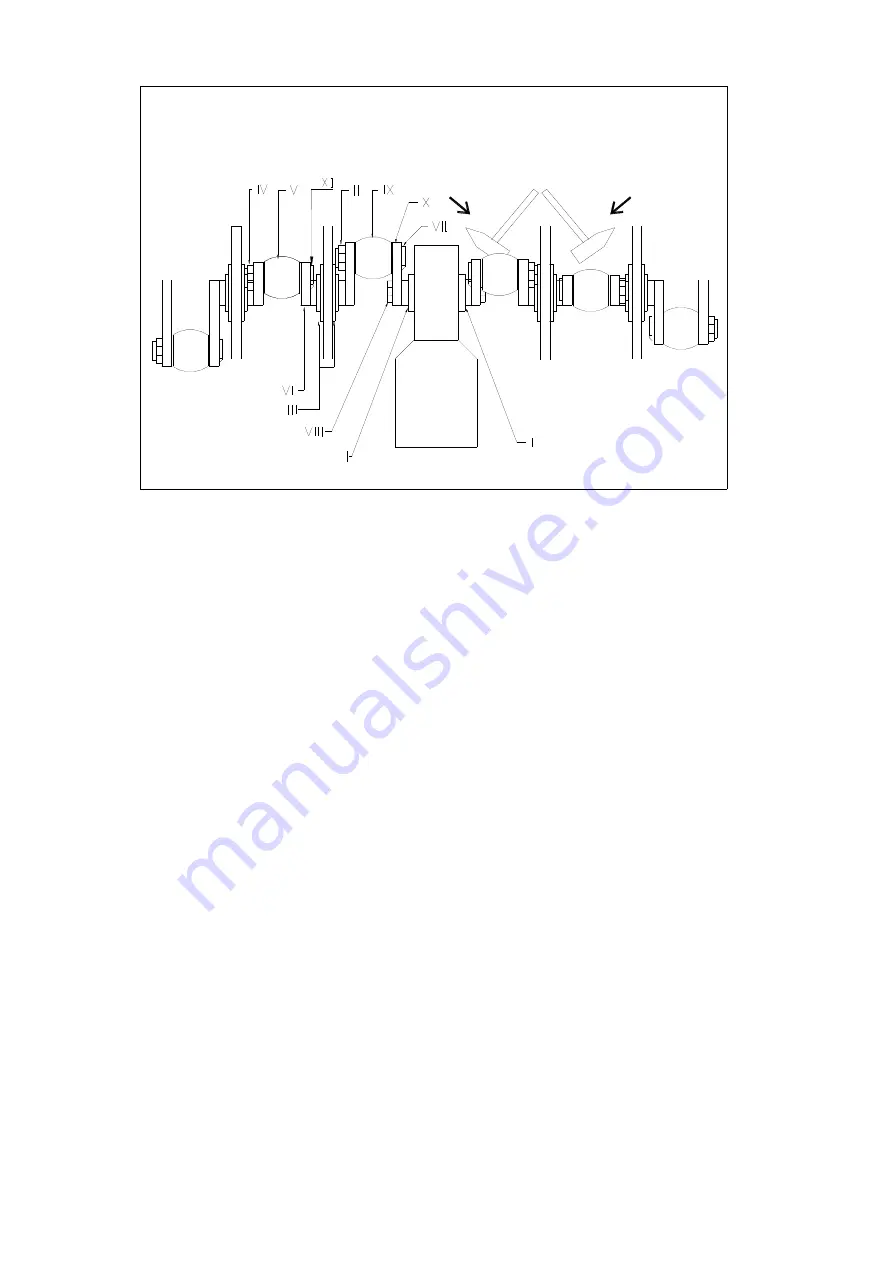

In fig.9. the assembly of the crankshaft is given. Also look at the spare part page for a more clear

view and set up. On a 7516 the angle between the handles on the gearbox should be 60 degrees.

15.2.1 REPLACING THE TRANSMISSION OIL SEAL.

In fig.9. a top view of the crankshaft is given. To replace an oil seal at the transmission, handle as

follows:

1. Loosen nuts II and IV, which may be tight through the loctite. Some heat may help.

2. Remove big end V, after the big end pin XI is removed.

3. Remove cover III by unscrewing all the bolts/nuts.

4. Slide crank VI away from the gearbox using a hammer and hitting is slightly at the centre, until big

end pin VII is free.

5. Rotate crank VI and slide big end IX from the big end pin VII.

6. Remove handle X after marking the position and removing nut VIII.

7. Pull oil seal out with a screw driver.

8. Clean area and assemble new oil seal.

9. Clean handle X and splined shaft and assemble the handle at the right position.

10. Before attaching nut/new lock plate, first fill the space under the locking plate (between the

splines and the handle) with liquid silicon paste.

11. Attach a new locking plate and nut VIII. Use loctite for the nut as well.

12. Assemble the other parts the same way as they have been removed.

13. If the crankshaft seems lumpish, see further 15.2.3.

Fig.9.