Chapter 7 - MAINTENANCE INFORMATION

RC GROUP S.p.A I_TRP_0909_GB

44

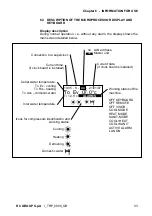

7.4 TABLE OF MAINTENANCE JOBS ON SCROLL COMPRESSOR

IMPORTANT

At each refrigerant substitution also change the oil.

At each refill of refrigerant or intervention on the refrigerant

circuit, verify the oil and motor insulation.

7.5 CHECKING OF THE PRESSURE VESSELS

It is very important to prevent rust formation on the surface of the

machine’s pressure vessels (evaporator, condenser, reclaim exchanger,

liquid receiver) and that there are no warps.

DANGER – FOR YOUR SAFETY

In the presence of any warps, stop the machine and contact an

After-Sales Service authorized by the manufacturer.

Periodically protect the pressure vessels with paints and/or antioxidant

products.

7.6 CHECKING OF THE WATER FLOW AND CLEANING OF THE

EXCHANGERS

The variation in the flow rate in the exchangers can be caused by the

presence of dirt in filters, by pump wear or wrong manoeuvres, as well

as by the presence of fouling inside the exchangers.

In this case, a chemical wash with suitable products must be carried out.

7.7 EXTRAORDINARY

MAINTENANCE

In the event that any extraordinary maintenance jobs are necessary,

contact an After-Sales Service authorized by the manufacturer.

IMPORTANT

In case of non-compliance with the above recommendations, the

manufacturer may not be held liable in respect of any safety

requirements of the machine and, during the warranty period, the

related rights will no longer be valid.

Every 1000 h or 3 months

Check the oil level

(if the gauge glass is present)

Checking for any vibration and noise

Checking of the motor insulation

Checking of regulations and safety devices

Checking leaks