Page 21

8. Troubleshooting

Warning! Before machines are dispatched from the factory, they have already

been checked thoroughly. The machine should not be tampered with or

altered. Maintenance must be carried out carefully. If any wire becomes loose

or is misplaced, it maybe potentially dangerous to user! Only professional

maintenance personnel should repair the machine!

Ensure the power is disconnected before working on the machine. Always wait

5 minutes after power switch off before removing the panels.

9.1. Common malfunction analysis and solution

The symptoms listed here may be related to the accessories, gas,

environmental factors, and power supply you use. Please try to improve the

environment and avoid such situations.

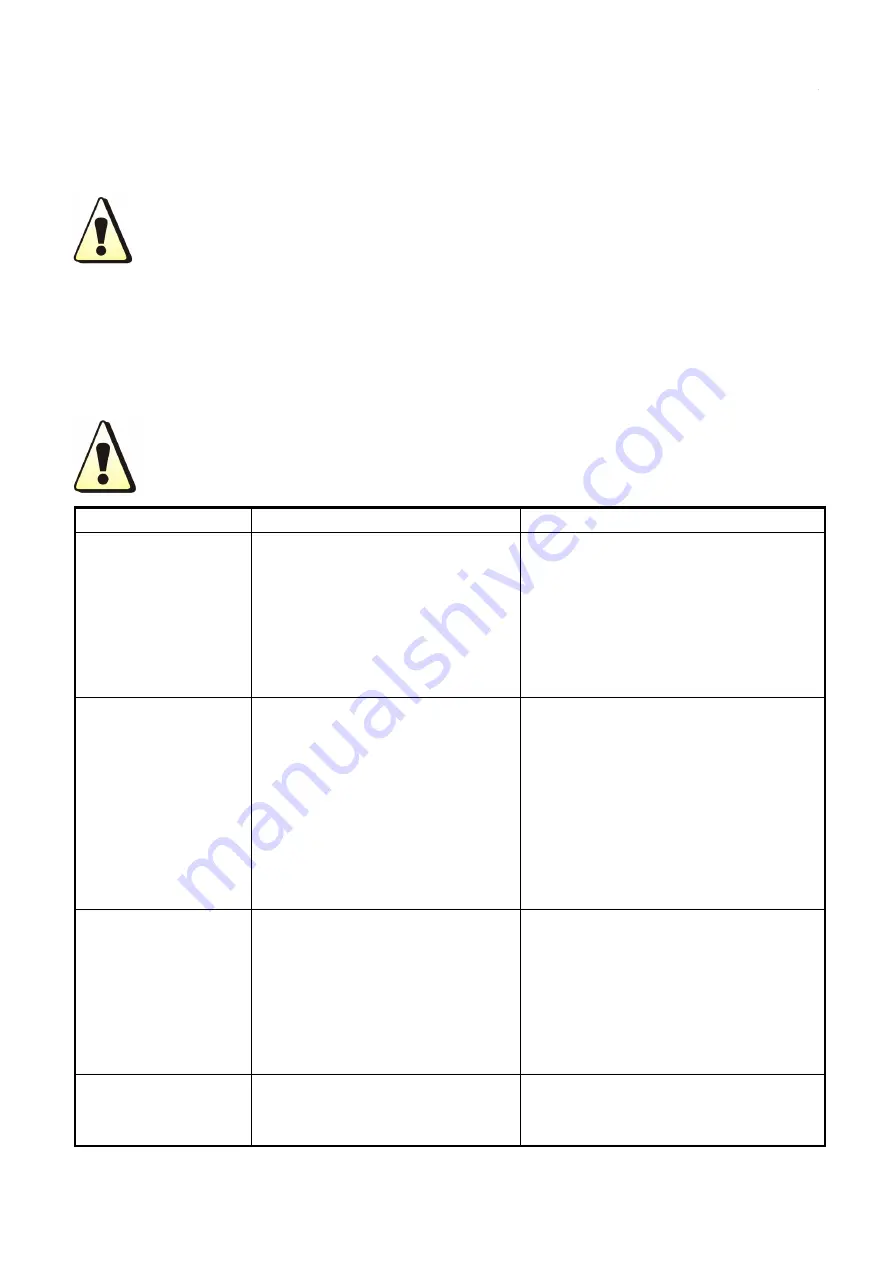

Symptom

Reasons

Troubleshooting

No pilot arc after

pressing the torch

trigger

·The machine is in gas check

mode

·The torch trigger circuit is

blocked

·Compressed air is not

connected

·The pilot arc circuit is damaged

·Turn off the gas check function or

wait 20s to exit automatically

·Check the torch trigger circuit

·Reconnect the compressed air

·Replace or repair the mainboard

Intermittent or

extinguished pilot

arc

·Serious wear and tear on parts

·Input compressed air pressure

too high

·Too much moisture or

impurities in the compressed air

·Pilot arc time exceeds 2s

·Replace with new consumables

·Adjust the pressure of compressed

air to 0.35-0.55MPa through the gas

regulator on the rear panel

·Manually drain the water in the filter

cup of the gas regulator on the rear

panel or replace the regulator

·Don’t press the torch to keep pilot

arc for a long time without cutting.

The pilot arc cannot

be transferred to the

workpiece

·The cutting circuit is blocked

·The distance between the

nozzle of the cutting torch and

the workpiece is too large

·Check whether the earth clamp is

damaged and clean the contact part

of the clamp and the workpiece to

ensure good metal to metal contact

·Ensure that the distance between

the tip of the cutting torch and the

workpiece remains within 3-5mm

Poor cutting quality

·The cutting current and speed

do not match the thickness of

the workpiece

·Select the standard cutting

operation; refer to Table 7.1.3

Cutting Process Quick Reference

Содержание RAZORCUT45

Страница 1: ...RAZORCUT 45 INSTRUCTION MANUAL JRWCUT45di AUGUST 2022 di...

Страница 24: ...Page 24 Appendix 1 Wiring diagram of CUT45PFC...

Страница 25: ...Page 25 Appendix 2 Exploded view drawing of CUT45PFC...

Страница 36: ...JASIC TECHNOLOGIES AMERICA INC 25503 74th AVE A KENT WA 98032 U S A WWW RAZORWELD COM SALES RAZORWELD COM...