15

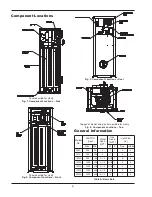

Table F: Heater Rates of Flow and Pressure Drops

Notes: Basis for minimum flow is ∆T . Basis for maximum flow is gpm.

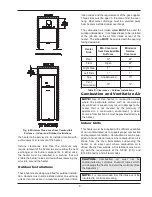

Piping

All high points should be vented. A heater installed

above radiation level must be provided with a low wa-

ter cut-off device (sales order option F-10). This

heater, when used in connection with a refrigeration

system, must be installed so that the chilled medium is

piped in parallel with the heater with appropriate

valves to pre-vent the chilled medium from entering

the heater.

The piping system of a hot water heater connected to

heating coils located in air handling units where they

may be exposed to circulating refrigerated air, must be

equipped with flow control valves or other automatic

means to prevent gravity circulation of the heater

water during the cooling cycle. It is highly recommend-

ed that the piping be insulated.

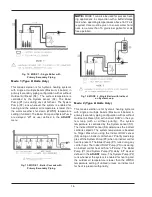

Air-Separation/Expansion Tank

All heaters should be equipped with a properly sized

expansion tank and air separator fitting as shown in

Fig. 11.

Fig. 11: Air-Separation/Expansion Tank

Three-Way Valves

Three-way valves intended to regulate system water

temperatures by reducing flow in the boiler should not

be used. Raypak heaters are high-recovery, low-mass

heaters which are not subject to thermal shock.

Applications & Modes

The VERSA IC Control system is designed for a wide

range of applications. The installer/design engineer

should refer to the following Modes to determine which

best fits the intended application and functionality for

the unit being installed.

Type H models of MVB have three modes available to

them to address the various applications the units can

be applied to. Type WH units will only have the WH

configuration available to them for use with potable

water applications when directly connected to a hot

water storage tank.

NOTE:

Hot water heating systems all have unique

levels of operating diversity that must be accounted

for in the system design. The system should always

include adequate system flow in excess of the

connected boiler flow for proper operation. Where

the system flow may drop below the connected

boiler flow a buffer/decoupler may be needed.

Failure to design for adequate flow (i.e. bypasses, 3

way control valves, flow limiting balance devices,

buffer tanks, etc.) will result in boiler short cycling

and may reduce boiler life. Always contact your local

Raypak representative for system design assistance

to avoid these issues.

GPM

P

GPM

P

GPM

P

GPM

P

T

GPM

P

T

503A

44

2.8

29

1.4

N/A

N/A

25

1.1

35

100

11.3

9

753A

65

6.4

44

3.1

33

1.9

33

1.9

39

100

13.8

13

1003A

87

12.0

58

6.0

45

3.8

45

3.8

39

113

18.6

15

1253A

109

20.9

73

10.2

56

6.5

56

6.5

39

113

22.2

19

1503A

N/A

N/A

87

16.0

67

10.0

67

10.0

39

113

25.5

23

1753A

N/A

N/A

102

22.5

78

14.0

78

14.0

39

113

27.2

27

2003A

N/A

N/A

116

31.9

89

19.8

89

19.8

39

116

32.0

30

Max Flow

MVB

Model

20° T

30° T

39° T

Min Flow

Содержание 503A

Страница 43: ...43 WIRING DIAGRAM Models 503A 2003A...

Страница 59: ...59...

Страница 60: ...60 www raypak com Raypak Inc 2151 Eastman Avenue Oxnard CA 93030 805 278 5300 Fax 805 278 5468 Litho in U S A...