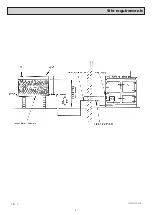

The oil supply connection between the storage tank and

the oil pipe should be run in copper or steel pipe with a

minimum diameter of 10mm. Galvanised pipes and

fittings should not be used. Annealed copper pipe is

preferred with flare type manipulative fittings. Capillary

fittings with soft solder should not be used. Steel pipes

should be joined using taper threads.

All pipe work and fittings must be completely air tight.

Only oil resistant compounds and PTFE tape should be

used when making joints. Pipe work must be protected

against damage whether fitted above or below ground.

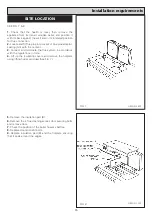

The size and arrangement of pipe work will depend upon

the distance and the height of the oil storage tank in

relation to the oil pump inlet.

The oil line from the storage tank to the appliance

must be fitted with a remote acting fire valve

operating at 150

˚

F, fitted with an appropriate length

of capillary to enable the valve body to be located

externally at the point where the oil line enters the

building. The heat sensing phial of the fire valve

MUST be fitted to the clips located behind the

terminal strip.

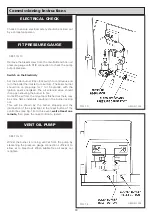

The 5-10 micron oil filter supplied with the appliance must

be fitted on the oil pipe and stop valve must be fitted, as

close to the cooker as possible in an accessible position.

A flexible pipe connection, approximately 500mm long, is

supplied to fit between the oil supply pipe and the oil

pump for ease of burner removal.

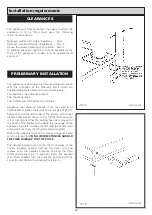

The minimum recommended oil tank size is 1400 litres

and the code of practice governing the installation are

covered by BS 5410 Part 1. Mild Steel Tanks should be to

BS 799 Part 5 and the Plastic Tanks to OFTEC standard

OFS T100.

Site requirements

6

OIL PIPE LINE

OIL STORAGE

Содержание Heatranger 480D

Страница 8: ...Site requirements 7 DESN 510519 FIG 1...

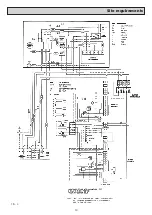

Страница 14: ...13 Site requirements FIG 4...

Страница 23: ...Sealed Systems 22...

Страница 24: ...23...

Страница 25: ...24...