Sealed Systems

See Fig 19.

a.

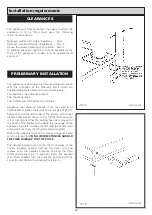

The installation must comply with the requirements of

BS 6798 and BS 449. Maximum water 82

˚

C + 3

˚

C.

b.

The safety valve set to operate 2 bar (30Ibf/In

2

) be

fitted in the flow pipe close to the boiler. There must not

be any valve between the safety valve and the boiler.

The valve should be positioned on a discharge pipe fitted

to prevent any discharge creating a hazard to occupants

or cause to damage electrical components and wiring.

c.

A pressure gauge covering at least the range 0 to 4

bar (0 to 60 Ibf/In

2

) shall be fitted in the system.

d.

A diaphragm type expansion vessel, to BS 4814, shall

be connected at a point in the return pipe close to the

boiler. The vessel must be chosen to suit the volume of

the water in the system and the charge pressure must

not be less than the static head at the point of

connection. Further details can be obtained from

“Materials and Installation Specification for Domestic

Central Heating and Hot Water” published by British Gas

and BS 7074:1.

Sizing Table:

A = System Volume Litres

e.

The hot water cylinder shall be either the indirect coil

type or a cylinder fitted with a calorifer.

f.

Water lost from the system shall be replaced from a

make-up vessel and non-return valve, mounted higher

than the top of the system on the return side of the

cylinder or radiators. Where access to a make-up vessel

would be difficult make-up can be provided by pre-

pressurisation of the system.

g.

The system may be filled from the mains via a

temporary hose connection from a draw-off tap supplied

from a service pipe under mains pressure, provided that

this pressure is acceptable to the local water authority.

See Fig. 20

SEALED SYSTEM REQUIREMENTS

Air or Nitrogen

charge pressure (bar)

Pre-Pressurisation

pressure (bar)

Expansion vessel

volume (Litres)

0.5

None 1.0

Ax Ax

0.07 0.120

1.0

None 1.5

Ax Ax

0.088 0.160

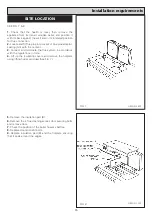

The following fittings should form a permanent part of

the system and fitted in the order stated (See Figs. 19 &

20).

(i) a stop valve complying to the requirements of

BS 1010: 2.

(ii) an anti-vacuum valve of a type approved by the

National Water Council.

(iii) a non-return valve of a approved type.

h.

Fill the system until the pressure gauge registers 1.5

bar (22Ibf/In

2

). Examine for leaks and rectify where

necessary. Refer to the commissioning instructions,

switch on the boiler burner and allow the system to reach

its maximum working temperature.

Examine for leaks then turn off the boiler.

Drain the system while it is still hot.

Refill, vent and adjust the cold fill pressure to the

required value.

Whilst, refilling the system it is recommended that a

corrosion inhibitor is added to the feed water.

Follow the commissioning instructions as for open

vented systems. See Section Commissioning

Instructions with the following additions:-

Fill the system until the pressure gauge registers 1.5 bar

(22Ibf/In

2

). Clear any airlocks and check for water

soundness.

Check the operation of the safety valve, by allowing the

water pressure to rise until the valve opens. The valve

should open within

+

0.3 bar (

+

0.43 Ibf/In

2

) of the pre-set

pressure. If this is not possible conduct a manual check

and test.

Release cold water to initial filling pressure.

Any set pointer gauge should be set to coincide with the

recommended filling pressure.

COMMISSIONING

21

Содержание Heatranger 480D

Страница 8: ...Site requirements 7 DESN 510519 FIG 1...

Страница 14: ...13 Site requirements FIG 4...

Страница 23: ...Sealed Systems 22...

Страница 24: ...23...

Страница 25: ...24...