The Rayburn is a floor standing combined cooker and

central heating boiler. It gives independent operation for

space heating, domestic hot water and cooking.

The appliance is fired by two independent pressure jet oil

burners. Either burner can be independently operated

under programmer control if required.

The boiler is designed for use on a fully pumped low

pressure hot water circulation system, with a pumped

over run facility or alternatively on a sealed system limited

to 2 bar.

IMPORTANT

❏

This appliance must only be used with Gas Oil to

35 seconds to BS2869: Class D

.

❏

An Indirect Cylinder to BS 1566: Part 1 must be

fitted.

❏

If the heating circuits are controlled in such a way

that both heating and cylinder circuits can be

closed off at the same time then a PERMANENTLY

OPEN BYPASS LOOP should be provided.

❏

A Fire Valve MUST be fitted in the oil supply line.

❏

The supplied in line filter MUST be fitted.

This appliance must be commissioned by a competent

engineer, such as OFTEC approved or a commissioning

engineer as shown on the Rayburn list.

The installation of the appliance must be in accordance

with the relevant requirements of the current Building

Regulations BS 7671: 1992 (formerly IEE Wiring

Regulations and the bylaws of the local Water

Undertaking. It should also be in accordance with the

relevant recommendations of the following current

British Standard Codes of Practice.

BS 5410

Installation of oil fired appliances for space

heating and hot water supply purposes. Part 1 Boilers of

rated output exceeding 45 kW.

BS 5449

Central Heating for domestic purposes. Part 1,

Forced circulation hot water system.

Building Regulations England & Wales

, Part J.

Heat producing appliances.

Building Standards Scotland

- Technical Standard Part

F. Heat producing appliances and storage of liquid and

gaseous fuel.

Building Regulations Northern Ireland

- Technical

Booklet to Part L. Heat producing appliances.

The control of Pollution (Oil) Regulations.

Appliance Hearth.

The surface temperature of the floor

below the appliance does not exceed 100

˚

C. The

constructional hearth described in Section J does not

apply. However, this appliance must be installed on a

solid floor of incombustible material which is capable of

supporting the total weight.

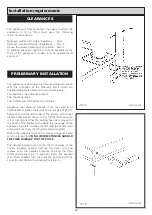

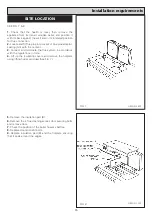

The location chosen for the appliance must permit the

installation and the provision of a satisfactory flue and an

adequate air supply. The location must also provide

adequate space for servicing and for air circulation around

the appliance. See ‘Installation of Appliance”.

The space in which the appliance is to be fitted must have

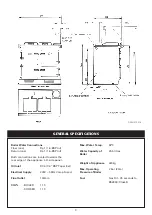

the following minimum dimensions:

Between wall and LH side of appliance - 3mm

Between wall and RH side of appliance - 10mm

Above the raised insulating cover handle - 60mm

In addition, adequate clearance must be available at the

front of the appliance to enable it to be operated and

serviced. Flue pipes and fitting must not be closer than

25mm to combustible materials and where passing

through a combustible partition such as ceiling or roof,

must be enclosed in a non-combustible sleeve providing

an air space of at least 25mm.

Space around the flue pipes passing through walls or

floors should be sealed against the passage of smoke and

flame, a fire stop valve must be provided where the flue

passes through a ceiling.

Where the cooker is to stand in a recess or against a wall

which is to be tiled,

in no circumstances should the

tiles overlap the cooker top plate.

Site requirements

5

REGULATIONS

LOCATION

INTRODUCTION

Содержание Heatranger 480D

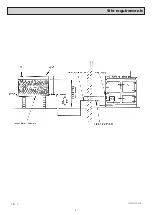

Страница 8: ...Site requirements 7 DESN 510519 FIG 1...

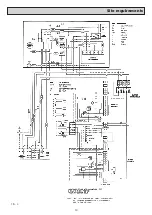

Страница 14: ...13 Site requirements FIG 4...

Страница 23: ...Sealed Systems 22...

Страница 24: ...23...

Страница 25: ...24...