:

23

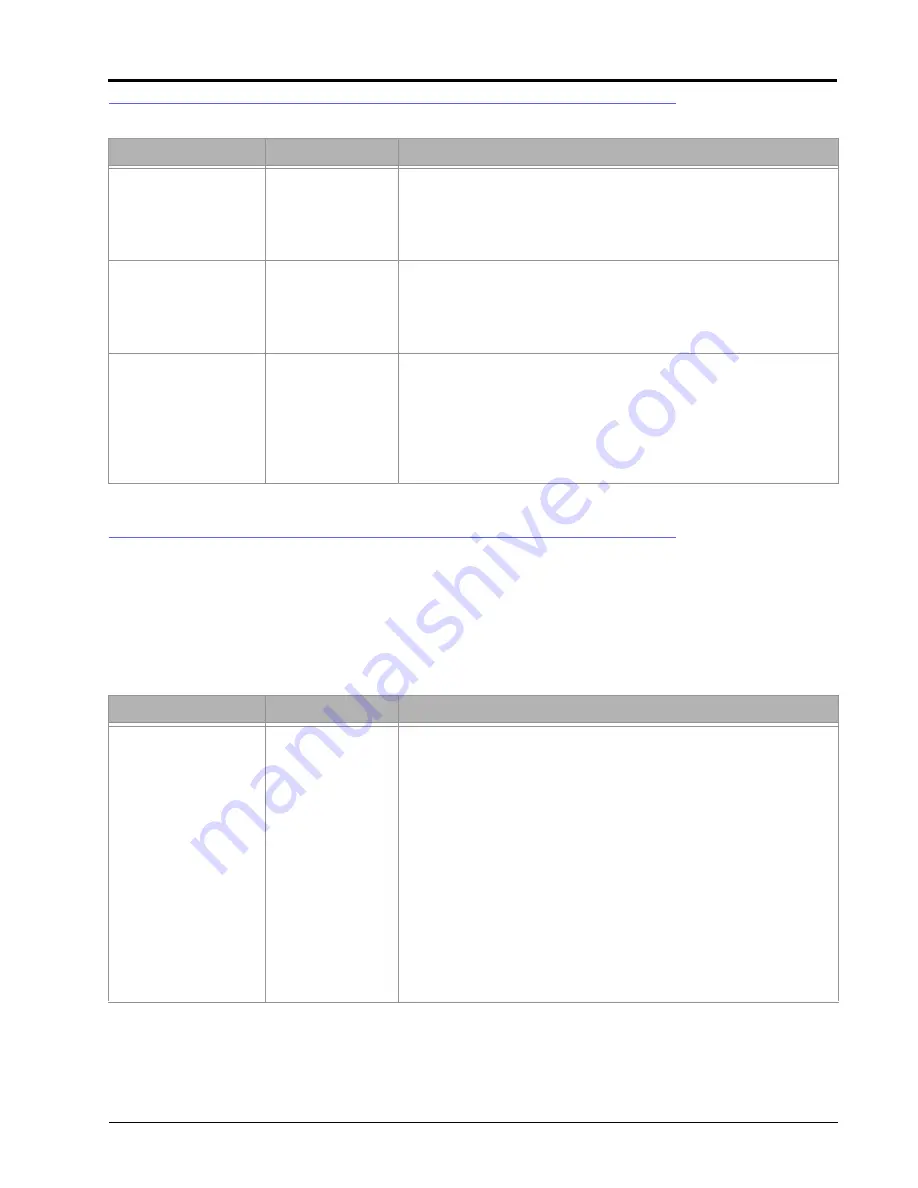

COVERAGE MAP ISSUES

CAN TROUBLESHOOTING

Although the control algorithm is located within the CAN node, all of the same troubleshooting techniques used

in a traditional hard-wired system still apply to a CAN system. CAN allows for modularization of the control

system, but the behavior of the system remains the same. Flow and speed sensors, as well as the control valve and

boom valves, are used in the same manner.

The following issues are some common causes for communication failures:

Issue

Possible Cause

Solution

Gaps displayed in

coverage map

Section widths not

configured correctly Check boom widths and boom center values

Guidance and

section widths not

the same

Set the guidance width and overall section widths to the same value.

Product coverage

displayed in zero rate

zones.

Vibration chatter in

encoder.

Make sure that the encoder is firmly mounted. Increase value in

“Zero Rate Tolerance.”

Valve or motor is

not set to close

completely

Adjust valve or motor to close or stop completely with no rate

applied.

Cannot achieve target

rate

Driving too fast for

vehicle

Speed may exceed capabilities of vehicle to deliver product. Slow

the vehicle down during application or configure product control

hardware to supply a higher amount of product.

Calibration

numbers incorrect

Check and adjust meter calibration, density, and other calibration

values.

Speed calibration

incorrect

Check and adjust speed calibration setting.

Issue

Possible Cause

Solution

Console or CANbus

cannot read the Switch

Pro nodes

Switch Pro is not

properly connected

Check Switch Pro auxiliary power connection.

Check the CANbus connection to the Switch Pro and re-initialize the

console to read the Switch Pro nodes.

No Power to Switch

Pro

Ensure console is powered on.

Check console power and ground lead connections. Refer to the

console’s Installation & Operation Manual for further console power

troubleshooting.

Weak or dirty

power to the CAN

nodes

Verify at least +10V DC is present on the auxiliary power output

connector.

Corrosion in CAN

connections

Disconnect and clean the CAN connections.

Check the CAN terminators.

CANbus not

terminated properly

Make sure that both ends of the CANbus systems are properly

terminated.

Содержание Switch Pro

Страница 17: ...13 FIGURE 2 Viper Pro with Switch Pro for SCS 440 450 Cabled Systems...

Страница 19: ...15 FIGURE 4 Viper Pro with Switch Pro for SCS 4400 Cabled Systems...

Страница 21: ...17 FIGURE 6 Viper Pro with Switch Pro Combo Cable for SCS 440 450 Cabled Systems...

Страница 23: ...19 FIGURE 8 Viper Pro with Switch Pro Combo Cable for SCS 4400 Cabled Systems...

Страница 24: ...APPENDIX B 20 Raven Switch Pro Installation Reference Manual...

Страница 28: ...APPENDIX C 24 Raven Switch Pro Installation Reference Manual...

Страница 30: ...Index 22 Raven Switch Pro Installation Reference Manual...