32

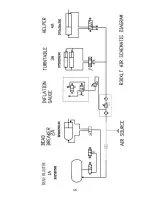

TuRNTABLE DRIVE BELT

INSPECTION / ADJuSTMENT

1. Remove the Side Panel. (See Fig 15.13)

2. Loosen the four Motor mounting bolts and nuts. Inspect

the Drive Belt for cracking and wear and replace as neces-

sary. Adjust the Belt deflection to 3/8” - 1/2”. (See Fig 15.14)

INfLATION VALVE LuBRICATION

1. Remove the Side Panel. (See Fig 15.13)

2. Disconnect Air Supply to machine. (See Fig 15.15)

3. Disconnect the Air Line going to the left port on the Infla-

tion / Bead Blast Pedal. Place 1/2 oz. SAE 10W non-deter-

gent oil or an air tool oil into the open port. (See Fig 15.16)

4. Operate the Inflation Pedal six times to work the oil into the

Valve. (See Fig 15.17)

5. Reconnect the Air Line and Air Supply and install the side

panel when service/adjustments are complete.

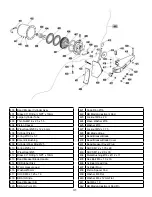

TRANSMISSION INSPECTION / LuBRICATION

1. Rotate the Turntable so that the Transmission fill plug is

visible and remove plug. (See Fig. 15.18)

2. Put a flexible wire into the Transmission Oil Fill Hole until

the wire hits the bottom of the well. (See Fig 15.19)

Fig 15.14

Fig 15.13

Fig 15.16

Fig 15.15

Disconnect

Air Supply

DANgER!

THE MOTOR ON THIS MACHINE CONTAINS HIGH

VOLTAGE. DISCONNECT POWER AT THE RECEP-

TACLE BEFORE PERFORMING ANY ELECTRICAL

REPAIRS. SECURE PLUG SO THAT IT CANNOT BE

ACCIDENTALLY PLUGGED IN DURING SERVICE.

Disconnect Tube

and Lubricate in Port

Inspect and adjust

deflection to ⅜” - ½”

Fig 15.17

Fig 15.18

Содержание R30XLT

Страница 34: ...34 ...

Страница 38: ...38 ...

Страница 43: ...43 ...

Страница 45: ...45 ...

Страница 46: ...46 RECORD ALL MAINTENANCE NOTES AND SERVICE HISTORY HERE ...

Страница 47: ...47 TIRE AND WHEEL DATA ...