21

ALLOY WHEELS-

Some manufacturers offer wheels with little or no drop

center. These are not DOT approved. The tire or wheel - or

both - can be damaged and the tire could explode under

pressure, resulting in serious injury or death. If you attempt

to mount/demount this type of wheel, use extreme caution.

(See Fig 12.1)

EUROPEAN PERFORMANCE WHEELS

(ASYMMETRICAL HUMP)-

Some European wheels have very large humps except

near the valve hole. On these wheels, the beads should be

loosened at the valve hole on both the upper and lower

sides first.

WHEELS WITH TIRE PRESSURE WARNING

SENSORS-

Performance wheels on some vehicles have a pres-

sure sensor strapped to the rim opposight the valve hole

or mounted on the valve stem. On these wheels, the beads

should be loosened at the valve hole on both upper and

lower sides first. (See Fig 12.2)

DEMOuNTINg TuBE TYPE TIRES

1. After both tire beads are loosened, lubricate the beads

and rim liberally.

2. Position the demount head and bead lifting tool as

described earlier paying careful attention not to pinch the

tube. Depress the table top pedal and rotate only a short

distance at a time. This allows you to stop the process

should you suspect the tube is getting pinched.

3. After upper bead is demounted, remove tube and

demount lower bead.

SECTION 13

MOuNTINg

1. Inspect the wheel closely for damage. Clean the wheel

and remove any light corrosion or rubber residue. Do not

attempt to service heavily corroded wheels. (See Fig 13.1)

2. Inspect tire for damage, paying close attention to the

beads. Verify size match between tire and wheel. (See Fig

13.2)

3. Lubricate both tire beads liberally with tire manufacturer’s

approved lubricant. (See Fig 13.3)

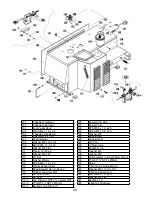

Fig 12.2

REMEMBER:

TABLE TOP ROTATION CAN BE STOPPED AT ANY

TIME BY REMOVING YOUR FOOT FROM THE ROTA-

TION PEDAL. NORMAL TABLE TOP ROTATION

FOR DEMOUNTING IS CLOCKWISE. DEPRESS THE

TABLE TOP PEDAL TO ROTATE THIS DIRECTION.

TO ROTATE THE TABLE TOP COUNTERCLOCKWISE,

LIFT THE PEDAL UP WITH YOUR TOE.

Fig 12.1

Fig 13.1

Fig 13.3

Fig 13.2

wARNINg!

THE RIM AND BEAD MUST BE LIBERALLY

LUBRICATED. FAILURE TO USE AN ADEqUATE

LUBRICANT CAN LEAD TO THE BEAD BINDING ON

THE RIM AND LEAD TO DAMAGE TO THE MOTOR

AND OR VOID THE WARRANTY.

Содержание R30XLT

Страница 34: ...34 ...

Страница 38: ...38 ...

Страница 43: ...43 ...

Страница 45: ...45 ...

Страница 46: ...46 RECORD ALL MAINTENANCE NOTES AND SERVICE HISTORY HERE ...

Страница 47: ...47 TIRE AND WHEEL DATA ...