Installation Manual

Combi - cod. 99943NA – November 2002

6

COLD WATER INLET

R

G

F

A

R

C

G

R

HOT WATER OUTLET

RETURN

FLOW

GAS

G

C

F

A

C

F

A

Fig. 3

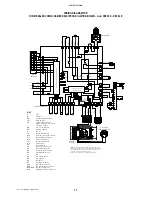

MINIMUM DISTANCES FOR FIXING TO WALL

To allow access in the boiler for maintenance operations, the minimum distances

shown below must be respected (fig. 1):

To facilitate installation, the boiler is supplied with a template for advance location of

connections to pipes. In this way, you may simply hook up the boiler when wall work is

completed (fig.2).

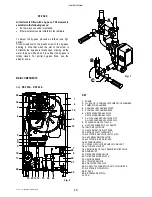

Installation Instruction

1) With a spirit level, draw a line on the wall on which the boiler will be installed (fig.

1).

2) Position the top of the template on the line drawn with the spirit level (respecting

the distances – see fig. 1) than mark the three points for insertion of the 3 screw

anchors or wall anchors for fixing the boiler hanging bracket. (choose proper

anchors according to the wall type). Next, mark the two points for insertion of the

two screw anchors for fixing the JIG to wall.

3) Fix the hanging bracket and the JIG.

4) Make connections to the hot and cold water supply, to the gas pipe and to the

heating system with the fittings supplied with the boiler JIG. Connect pipes and

valves as shown in the picture

5) Position the boiler paying attention to hang it to the hanging bracket (do not lean

the boiler on the JIG) and make final connections.

WATER CONNECTIONS

To facilitate installation, the boiler is equipped with a fittings kit (see fig. 3 and 4).

IMPORTANT

:

Before connecting the heating system pipes, carefully clean the system to prevent residual dirt from entering into circulation and negatively

affecting boiler function. Install a funnel with discharge under the safety valve (calibrated to 3 bar) to collect water in case of leaking due to

overpressure.

No safety valve is needed for the domestic hot water circuit, but if the cold main inlet pressure exceeds 5 bar a pressure

reducing value should be fitted.

•

avoid using pipelines of reduced diameter;

•

avoid the use of tight bends and adapters in important sections;

•

clean out the system thoroughly before connecting up the boiler in order to eliminate any residue left in the pipes and radiators.

N.B.:

Make sure that the water and heating pipes are not used as earth connections for electrical apparatus.

2

1

30

0

40

0

3

450

4

60 450

60

F

R

G

C

A

ST

Fig. 2

Fig. 1

MINIMUM DISTANCES mm.

FIXING KIT

Fig. 4

FIXING JIG

W/VALVES

Содержание RSF 24 E

Страница 2: ......