Installation Manual

Combi - cod. 99943NA – November 2002

2

TECHNICAL DATA

Type C unit

Type C devices are devices in which the combustion circuZ

it (air intake, combustion chamber, exchanger, combustion

exhaust) is sealed off from the place where they are installed.

CENTRAL HEATING - DOMESTIC HOT WATER

sealed combustion circuit type

RSF 20 E -

electronic ignition

RSF 24 E -

electronic ignition

Technical data

MODEL

RSF 20 E

RSF 24 E

Maximum rated input

KCal/h

22900

25628

Kw

26.6

29.8

BTU/h

90867

101692

Minimum rated input

KCal/h

11000

15000

Kw

12.8

17.5

BTU/h

43648

59250

Maximum rated output

KCal/h

20900

23090

Kw

24.34

26.85

BTU/h

82931

91621

Minimum rated output

KCal/h

9450

12900

Kw

11

15

BTU/h

37498

51187

Heating temperature adjustment

°C

30-80

30-80

Max. working pressure (heating)

bar

3

3

Min. working pressure (heating)

bar

0.3

0.3

Expansion vessel capacity (initial pressure 1 bar)

Litres

8

8

Hot water flow rate

∆

t 25°

Litres

13

15

Max. working pressure (water)

bar

6

6

Min. working pressure (water)

bar

0.5

0.5

Width mm.

450

450

Height mm.

860

860

Depth mm.

345

345

Weight Kg.

49

49

Coaxial exhaust flue diameter

Double exhaust flue diameter

100/60

80/80

100/60

80/80

Flow/return connections

Ø

3/4” - 3/4”

3/4” - 3/4”

Cold water connections

Ø

1/2”

1/2”

Hot water connections

Ø

1/2”

1/2”

Gas connections

Ø

1/2”

1/2”

Electrical connection 50 Hz

V

230

230

Power supply

W

170

170

Burner jets NP 13 G30

Ø

1.25

1.25

Burner jets NP 13 G30

Ø

0.75

0.77

Gas category:

IT II2H3

Gas supply pressure:

G20

20 mbar /

G30/31

29-30/37 mbar

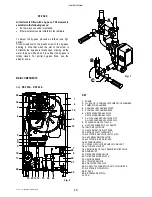

FORCED CIRCULATION

Coaxial vertical

Coaxial horizontal

C32

C12

C52 Double

Содержание RSF 24 E

Страница 2: ......