MAINTENANCE INSTRUCTIONS

42

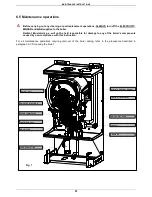

Cleaning the main exchanger module and

combustion unit (see fig. 1)

•

Disconnect the electrical connections of the

electric fan.

•

Disconnect the joint and remove the pipe linking

the gas valve to the injector unit (venturi).

•

Disconnect the joint and remove the gas feed

pipe from the gas valve.

•

Un-plug the ignition electrode and flame

detection wires from the ignition control unit.

•

Unscrew the ring-nut at the bottom of the room-

sealed chamber and remove the gas valve.

•

Unscrew the nuts securing the burner unit

(consisting of a fan, manifold and burner) to the

primary heat exchanger.

•

Remove the burner unit, paying particular

attention not to remove the ceramic fibre

protection from the bottom of the heat exchanger.

•

Check that the burner is not affected by deposits,

scaling or excessive oxidation. Check that all the

holes in the burner are free;

•

Clean the electrodes carefully without altering

their positions with respect to the burner;

•

Clean the burner cylinder using a non-metal

brush and without damaging the ceramic fibre;

•

Check the integrity of the washer on the cover of

the burner;

•

Clean the heat exchanger (see fig. 2) using a

household

detergent

for

stainless

steel,

distributing the product on the spirals of the

exchanger using a brush. Do not wet the ceramic

fibre coating. Wait a few minutes then remove the

deposits using a non-metal brush. Then remove

the residues under running water;

•

Remove the pipe clip, remove the condensate

drainpipe and clean under running water.

•

Unscrew the joint to the condensate trap, remove

the trap and wash under running water.

•

With the cleaning completed, re-assemble the

components following the above procedure in

reverse order and replacing washers where

necessary.

•

Finally, check the soundness to make sure that

all gas and exhaust joints are tight.

Fig. 1

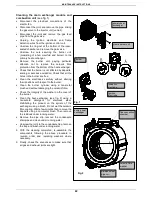

premix burner unit

burner

ionisation

electrode

ignition

electrode

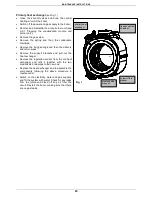

primary heat

exchanger

B

A

primary heat

exchanger

flue connection

chamber

stainless steel

pipe coil

ceramic fibre

washer

Fig. 2