24

HL2-DS

Series

When connecting piping to the unit, the use of a thread joint compound is required. The thread

compound (pipe dope) shall be resistant to the action of liquefied petroleum gas or any other

chemical constituents of the gas to be conducted through the piping. Use of Teflon

®

tape is not

permitted.

WARNING

!

Always use two (2) opposing wrenches to tighten mating pipe connections

to prevent excessive torque on the gas valve and manifold pipe. Excessive

torque can damage the valve and/or misalign the orifice, resulting in fire,

explosion, serious injury, or death.

Leak Testing

Always leak test final gas assembly for gas leaks according to the procedures outlined in NFPA 54 and

all local codes and/or Standards.

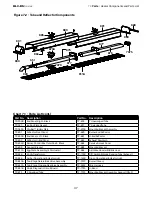

For leak testing on pressures below ½” PSI

Before leak testing, close the field installed manual shut off valve shown on Figure 3.14 on the supply

line to isolate the gas valve from the pressure.

NOTE:

All factory installed gas connections have passed an approved leak test.

For leak testing on pressures above ½” PSI

When leak testing with pressures above ½” PSI (14” W.C.), the unit must be isolated from the supply

pipe. Close the field installed manual shut off valve, disconnect the supply line to the unit, and

temporarily cap the supply line for testing purposes.

WARNING

!

Use a soap solution or equivalent for leak testing. Never test for leak with an open

flame. Failure to comply could result in personal injury, property damage, or death.

WARNING

!

Gas pressures to the appliance controls must never exceed 14” W.C. (1/2” PSI). Supply

pressures greater than 14” W.C. can damage the controls, resulting in personal injury,

property damage, or death.

3.0

Installation

•

Gas Supply Installation Instructions

•

Leak Testing

Содержание HL2-DS Series

Страница 39: ...39 HL2 DS Series 7 0 Maintenance Notes Notes ...