7

Problem solving

Warnings

•

Before starting any maintenance or repairs, close the air outlet valve and press the

test button on top of the electronic water drain to depressurise the air system.

•

Apply all relevant instructions in section

Safety precautions during maintenance or

Faults and remedies

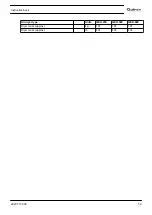

Condition

Fault

Remedy

Pressure dew point too high

Air inlet temperature too high

Check and correct. If necessary,

install a pre-cooler

Ambient temperature too high

Check and correct. If necessary,

draw cooling air via a duct from a

cooler place or relocate the

dryer.

Air inlet pressure too low

Increase inlet pressure

Dryer capacity exceeded

Reduce air flow

Shortage of refrigerant

Have circuit checked for leaks

and have the refrigerant circuit

recharged

Condition

Fault

Remedy

Condenser pressure too high or too

low

Fan control switch out of order

Replace

Fan or fan motor out of order

Check fan/fan motor

Ambient temperature too high

Check and correct. If necessary,

draw cooling air via a duct from a

cooler place or relocate the

dryer.

Condenser externally clogged

Clean condenser

Condition

Fault

Remedy

Compressor stops or does not start Electric power supply to compressor

is interrupted

Check and correct as necessary

Thermic protection of refrigerant

compressor motor has tripped

Motor will restart when motor

windings have cooled down

On three-phase units, phase

sequence relay fault indication

Reverse two incoming electric

lines.

Instruction book

2920 7103 90

53

Содержание QED-250

Страница 2: ......

Страница 40: ...4 Installation 4 1 Dimension drawings QED 250 and QED 300 dimension drawing Instruction book 38 2920 7103 90...

Страница 42: ...4 2 Installation proposal Installation proposal QED 250 and QED 300 Instruction book 40 2920 7103 90...

Страница 43: ...Installation proposal QED 350 up to QED 600 Text on drawings Instruction book 2920 7103 90 41...

Страница 64: ......

Страница 65: ......