N.B. If the Ioader is equipped with hydraulic imple-

ment locking, remove stopping disc and hook for

locking lever - see mounting instruction for hydraulic

implement locking.

Always check, when changing implements, that the

implement is properly locked in position by pressing the

front end of the implement to the ground.

WARNING

A faulty designed implement could cause damage to the

loader. Therefore never mount an implement of another

make without making sure that the implement has been

approved by ALÖ.

ENGLISH (110:01)

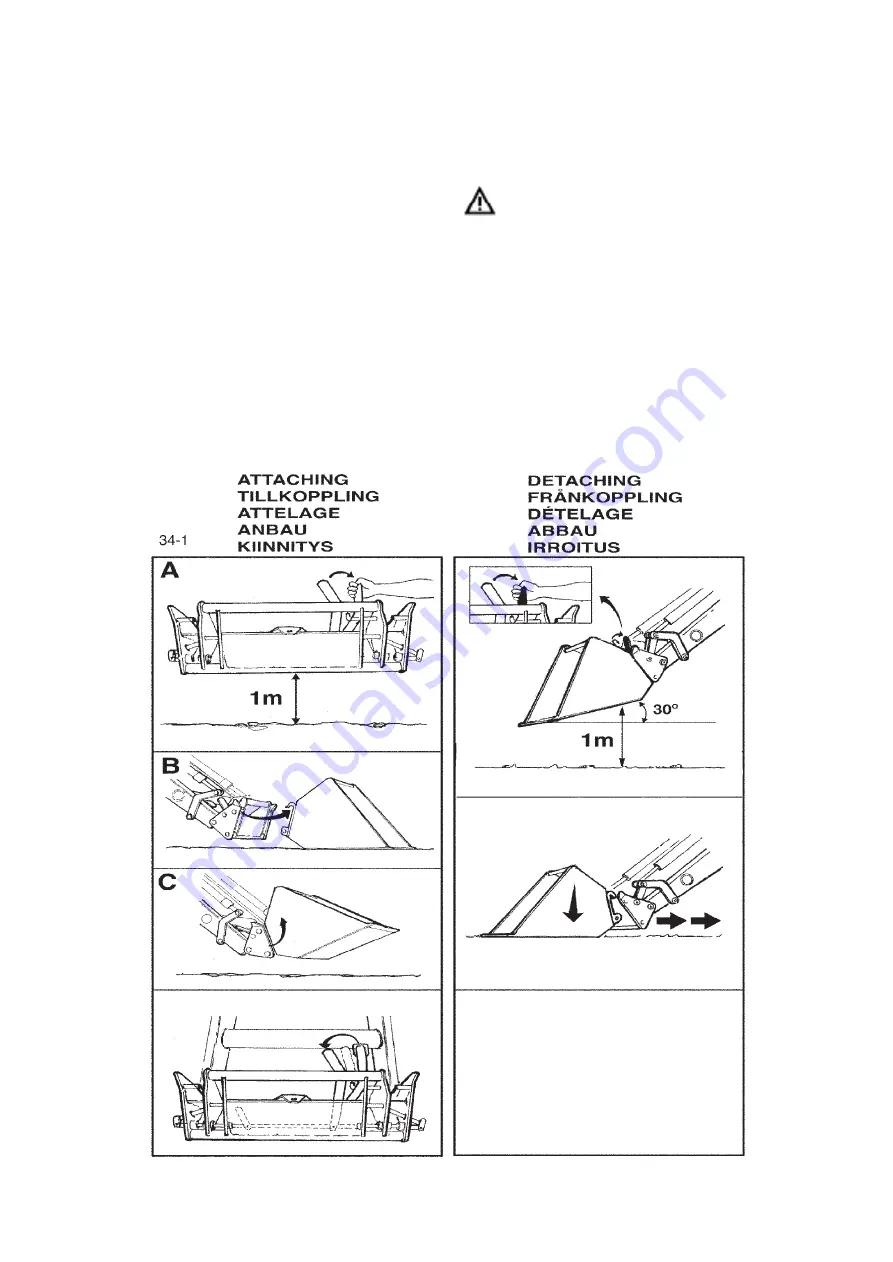

ATTACHING OF IMPLEMENTS

(applies to loaders with tool carriers of type EURO (8)

and EURO-Combi (3 +5 +8.)

- Place the operating lever in open position (left). This

will be easier if the loader beam is lifted 1 m. (Illus. 34

A)

- Incline the tool carrier slightly forwards.

- Drive the loader against the implement so that the

hooks on the implement engage correctly with the tool

carrier. (Illus. 34 B)

- Lift and tilt the implement backwards. The locking

lever will then be disengaged and the implement will be

automatically locked (Illus. 34 C).

110