QSA Global, Inc.

40 North Avenue Burlington, MA 01803

888.272.2242

781.272.2000

qsa-global.com

Operations Manual

MAN-038 March 2019

Page 39 of 100

e. Check the outlet port for proper function by attaching and removing a source guide tube

equipped with the appropriate bayonet connector. The operation should be smooth and

resistance free. If there is any resistance or ‘crunchy’ feeling noticed during attachment or

removal of the source guide tube or during movement of the outlet port cover, this indicates

excessive amounts of sand or dirt within the outlet port mechanism. The outlet port

mechanism must be removed, cleaned, inspected and lubricated according to the complete

service instructions.

f. Check the locking mechanism and plunger lock to verify attachment and operation. Grasp the

entire mechanism with one hand and attempt to shift the mechanism. Retaining screws that

have been loosened from excessive vibration or improper maintenance will allow the

movement of the locking mechanism during this check. Loose screws must be tightened

according to the annual maintenance requirements prior to use or transport.

g. Use the Model 550 NO GO gauge to check for wear on the remote control cable connector

and the source assembly connector. Replace all components of the “locking system” that fail

any of these tests.

h. Operationally check the automatic securing mechanism and then the function of the entire

system during the first radiographic exposure of the work shift while within a restricted area.

Operation of the radiographic system verifies both the automatic securing mechanism and

entire system operates smoothly and freely. If operation is faulty, remove the gamma-ray

source projector from service and perform the complete annual maintenance.

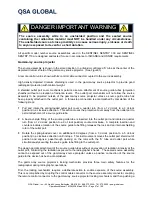

4.1.4 Misconnect Test

After performing the quarterly or annual maintenance, the complete radiography system must be

tested by the maintenance program administrator or Radiation Safety Officer. A misconnect test

on the gamma-ray source projector including the radioactive source assembly and remote

controls effectively tests the integrity of the entire locking system. This procedure detects long-

term wear (or damage) of the interrelated failsafe system including identification of any excess

wear on the control cable connector, the gamma-ray source projector’s automatic securing

mechanism and sealed source connectors simultaneously.

Note: Component wear occurs to both the control assemblies and the device locking

mechanisms over time, therefore, to ensure acceptable equipment operation, the

misconnect test must be performed on each device lock assembly and control

assembly that will be used for radiographic operations. All remote controls must

be tested using a QSA Global, Inc. manufactured automatic securing mechanism

equipped with a QSA Global, Inc. manufactured source assembly, 550 jumper or a

mock source assembly (A424-14XL for the SENTINEL SENTRY 110 and A424-13XL

for the SENTINEL SENTRY 330) to ensure the effectiveness of the misconnect test.