QSA Global, Inc.

40 North Avenue Burlington, MA 01803

888.272.2242

781.272.2000

qsa-global.com

Operations Manual

MAN-038 March 2019

Page 33 of 100

a foot. Radiographers can count the number of rotations of the crank handle when using control cranks

that are not equipped with odometers to obtain an approximation of the travel distance. One full

revolution of the crank handle is equal to approximately 10 in (25.4 cm) of travel on Model 692, 693 and

664 control cranks. One full revolution of the Model 882 and 885 control cranks is equal to approximately

12 inches (30.5 cm) of travel.

Two remote control conduits (sheaths, housings) are attached to the control crank. One conduit contains

the working side (also called “live side”) of the control cable that drives the source assembly out of the

gamma-ray source projector and through the source guide tubes. The second conduit is the reserve

(storage side) conduit containing the length of the control cable necessary for projection of the source

assembly. The remote control conduits provide a degree of protection of the control cable against the

elements common to the working environments that industrial radiography is performed.

Attached to the opposite end of the remote control conduits is a connecting plug assembly that is used for

attachment of the remote controls to the locking mechanism of the gamma-ray source projector. The

connecting plug assembly and the control cable connector are designed with minimal tolerances for

safety. A connection of the source assembly connector to the control cable connector must be completed

before the remote control connecting plug assembly can be attached to the locking mechanism of the

gamma-ray source projector. A protective end-cover must be installed after use of the remote controls.

The protective cover provides protection to the connecting plug assembly and the control cable connector

and prevents the ingress of water, mud, sand or other foreign matter.

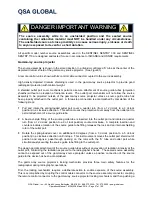

IMPORTANT WARNING

The control cable connector is a made from hardened steel and should never be left

unprotected or forced into connection with the source assembly as this could damage the

connector over time leading to possible breakage during use. Always use the protective end-

cover when remote controls are not connected to the gamma-ray source projector and always

manually move the sleeve of the female connector of the source assembly to the OPEN

position when connecting and disconnecting the control cable from the source assembly

.

The control cable (drive cable) is a flexible, steel cable with an outer helical winding. The length of control

cable is approximately twice the length of the remote controls. Attached to one end of the control cable is

a male connector. The control cable when used in conjunction with the remote control as a system

provides a positive mechanical control of the source assembly at a distance. The control cable is a critical

link for safe operation and is the radiographer's only means of control over the source assembly.

Therefore, the control cable's storage, use, daily inspection and quarterly maintenance are critical

elements to the prevention of a control cable failure. In almost all cases, repairs for a control cable are

not possible, with the exception of replacing the control cable’s Model 550 male connector every five

years. Damaged, defective or control cables with unknown origin (non-traceable) must not be used and

must be removed from service.