14

Assembly and installation manual

QIM/QDB Mixer Series

QIM/QDB-M01

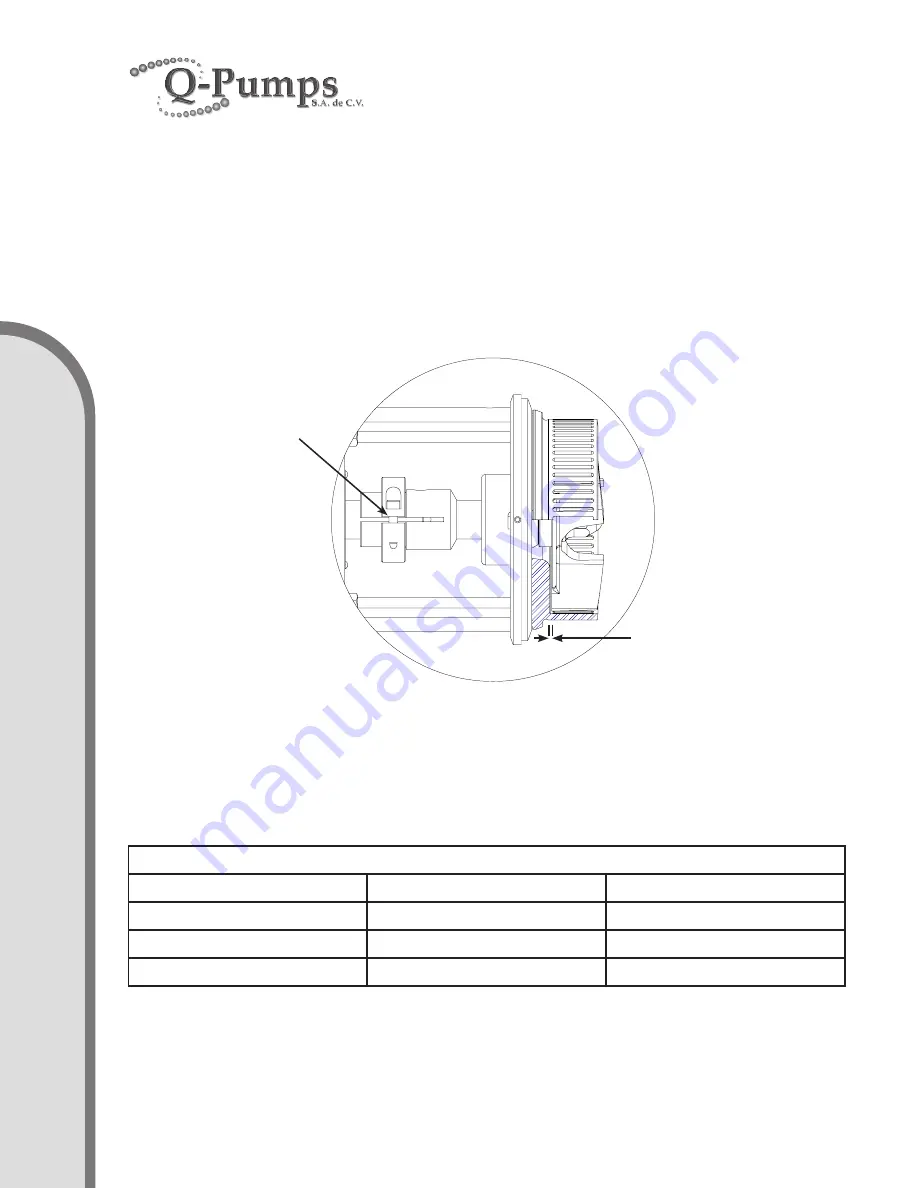

3d. Once the assembly is tightened place a spacer of 0.060” (1.53 mm) thru 0.070” (1.78

mm) between the back of the impeller and the front of the backplate. You may use a

caliper, some shims or a washer with that width to set the critical distance for the correct

performance of the mechanical seal. Keep aligned both, the stub shaft slot and the collar

slot before tightening the screws on the shaft collar. Compress the impeller against the

backplate with the spacer between them and proceed to tight the screw or screws on the

shaft collar. Now turn the impeller by hand, it must turn with no restriction. Check that

every blade is separated the distance indicated. Figure H.

Use the torque values for tightening the collar screws indicated in the Chart 2.

f

L

Figure H.

Chart 2.

Align stub shaft

and collar slots

0.060” (1.53 mm)

0.070” (1.78 mm)

Chart 2 – Torque values for tightening the stub shaft collar Allen screws

Torque ft-lb

Models NEMA

Models IEC

15

Frame 56 to 18

Frame 80 to 112

30

Frame 21 to 25

Frame 132 to 160

40

Frame 28 to 32

Frame 180 to 225

A

SS

EM

B

LY