Page 3 of 24

Operation of PCR Model

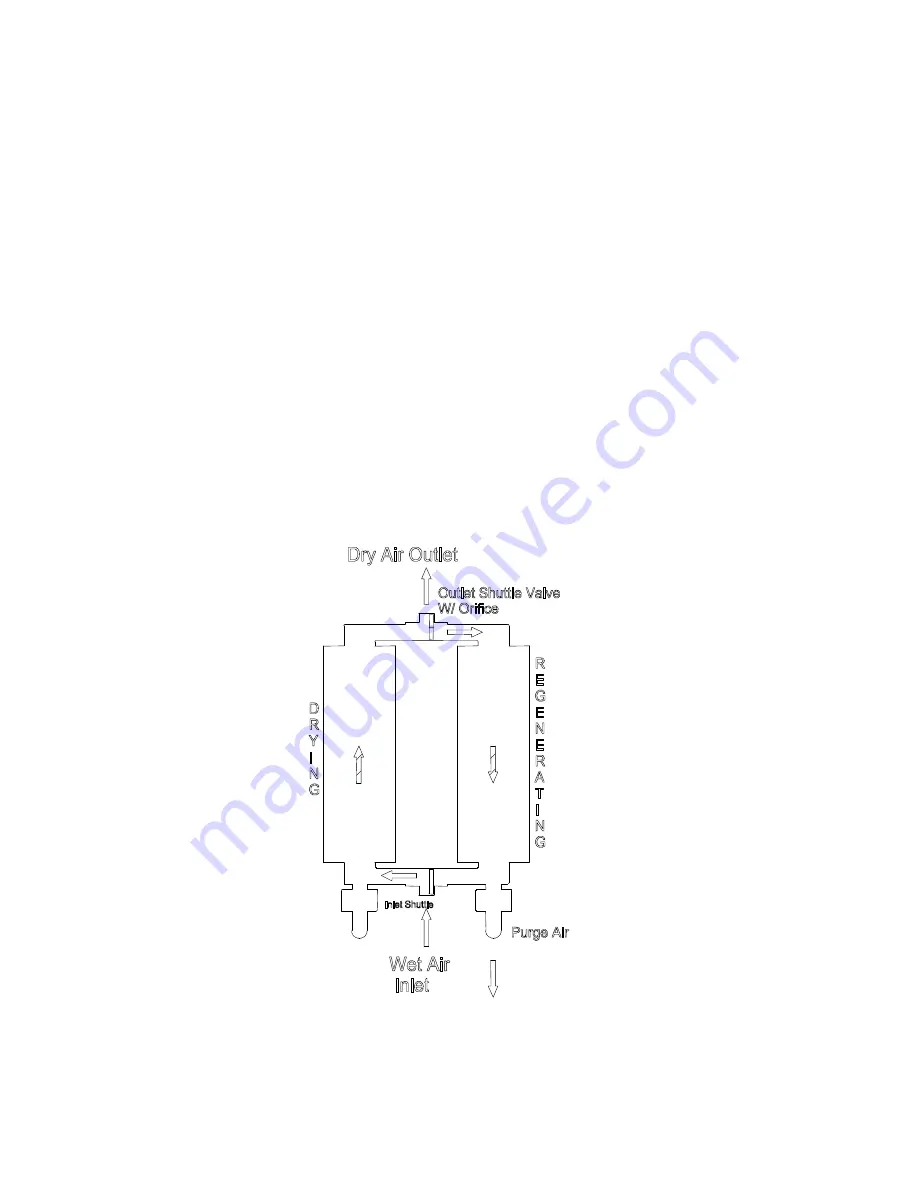

As previously described, the PCR model employs PSA technology to effectively remove

moisture (or other unwanted components) from a compressed air stream. It is, however,

configured differently than other PUREGAS models based on a common air manifold.

Instead of a manifold and 3-way valves to direct the airflow through the unit, the PCR

model uses shuttle valves and 2-way solenoid valves.

The inlet (lower) shuttle valve directs the compressed air flow into one of the two

desiccant chambers where nearly all of the water vapor is removed. The shuttle valve

contains an internal disk, which “shuttles” back and forth in the valve body based on the

pressure differential created by the 2-way valves (one of which is open and the other

closed).

The ultra-dry air leaving the desiccant chamber passes through the outlet shuttle valve

to the application. A precision orifice in the outlet shuttle disk, however, allows a portion

of the dry outlet flow to be redirected back through the off-line tower to purge it of the

accumulated moisture. The purge stream exits the unit through the open solenoid valve

directly below the chamber. The solid state timer controls the process by opening and

closing the solenoid valves every 60 seconds, which switches the inlet flow to the

regenerated tower.

FIGURE 2: OPERATION OF PCR MODEL