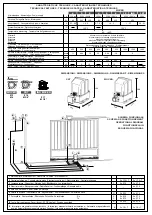

CSAFETY CRITERIA

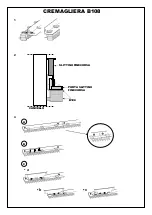

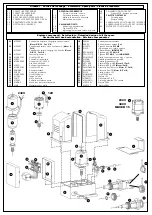

FASTENING OF RACK”B108”

(Fig D / E / F)

1

Attention: before beginning anykind of procedure of installation is absolutely

necessary to read all this manuall.

1

2

Choose the operator in the width’s function of the arm as proposed in the table

The relief studs of the clamp have to be perfectly embedded in the oval holes of the

below.

rack.

3

Check that:

2

.

-

The gate must slide perfectly (sliding wheels well greased).

3

-

The gate must be equipped with opening and closing mechanical stops.

4

5

INSTALLATION ADVICE

Installation:

6

•

All the connections must be made in absence of electricity.

7

•

Foresee a omnipolar breaking device near to the apparatus (the contact must

measure at least 3 mm)

8

Protect always the alimentation by an automatic switch of 6A, or by a monophase of

16A including the fuse.

9

•

The power supply lines to the motors, to the control unit and the connection lines to

the outfits must be separated to avoid troubles which could generate problems in

10

the installation working.

•

Any outfits (of control or safety) eventually connected to the control unit must be

tension free.

Spare parts:

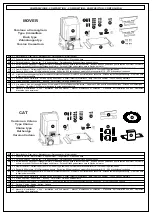

FIXING OF THE CHAIN

•

Use esclusively original spare parts.

The chain must be fixed to the supporting structure of the gate using the appropriate nuts

and screws.

1

Fix the two supports of the chain to the two ends of the gate at the appropriate

height. (Fig. I)

Installation:

Screw a stud to the first theaded strock. Insert the theaded stock in the clamp,

•

In order to correctly use the product and to exclude the possibility of injury or

2

controlling that the fixing hde of the chain is turned to the gear-motor.

damage, refer to the

"Generals"

page enclosure, which is an integrated part of this

Insert the 2° stud and tighten both in the middle of the caneer.

manual.

3

Screew a stud to the 2° threaded stock,put here a spring, and insert all in the hole of

•

The use of this equipment must be in observance of the safety standards in force in

4

the 2° clamp, controlling that the fixing hole of chain is turend to the gear-motor.

the country where it is installed, as well as the standards governing proper

Present the chain (take the chain) and cut it in order to be fixed ou the 2° holes of

installation.

5

threaded stocks.

Warranty:

Fix the chain ou the threaded stocks using the special joint.

•

The warranty supplied by the manufacturer becomes void in the event of

6

Unclamp the gear-motor with the special key.

interference, carelessness, improper use, lightening damage, power surges or use

Insert the chain between the pinion and the cilindric pin of the gear-motor sliding

by unqualified personnel.

guide. Pull the chain till to reach to the 2° threaded strock. Fix the chain to the 2°

•

The warranty will also become void in the event of the following:

threaded stock with the right joint. Put the chain in tension screwing the studs of both

Failure to observe the instructions given in the manuals supplied with the product.

the 2 clamps. We have the right chain tension when making leve, in every part of it

•

The application of any part in a manner differing from that provided for current

the spring which streches the chain have already the possibility to be pressed.

legislation or the use of spare parts which are unsuitable and/or not approved by

Controll that the distance between the chain and the cilindric pin is right to present

manifacturer.

7

the exit of the chain, from its guide without obstruct the sliding and eventually adapt

•

The manufacturer cannot be held responsible for damages due to improper or

the distance thickening the plate.

unreasonable use.

8

Fix ou the gate structur the special strocke end slides.

For the gate has not to go to knack against mechanic blocks, that it should have,

INSTALLATION INSTRUCTION SEQUENCE

regulate the special strake-end slides, so that the micro end-stroke little hammer

1

First of all, make au analysis of the risks refening to the

“Generalities”

belonging to

knock against the slide when the gate is near feco cm. to the complete closing.

this manual. Fill the technic table and cancel the highest risks.

In case of residual risks, make au installation with security systems.

Controll the security laws exposed in the

RELEASE OF THE ACTUATOR

2

“Security Criteria”

Insert the key in the release seat and turn it counterclockwise to release the gear-motor

3

Verify and controll all the components.

and clockwise to lock it. (Fig. C).

4

Identify the fixing point of the gear motor.

5

Postion and fix the gear motor.

6

Fix the chain or the rack

7

Make the sliding action of the gates by hand unclamping the motor.

8

Position all the accessoires.

9

Stretch the cables as in the

“Unctional Scheme”

10

Connect the central and all the accessoires.

11

Program the radio-receptor.

12

Program the central

13

Regulate the thrust power of the central.

14

Make some test manouvres.

In case of badworking, see the

“Anomalies and Counsuls”

If you do not find any slution coll the neatest Assistence centre.

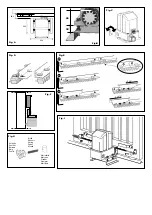

FIXING OF THE MORORIDUCER

-

Fasten perfecly the

P1

motor bracket to the ground respecting the measures shown

in the (Fig. A)

-

Fasten the gear-motor to the base plate (Fig. B) using the supplied bolts M10X60.

-

On each bolt screw two nuts M10 and two washers Ø10. (Fig. C)

The first nut is to fasten the gear-motor to the bolt, the second one is to fasten the

gear-motor to the base plate and for the fine adjustment of the height.

The fastening bolts allow a vertical adjustment of some 15 mm.

We recommend to place the built in the middle of each fixing botton of the gear-

motor.

We recommend to position the gear-motor lefting move or less 30 mm between the

base-plate and the gear-motor (Fig. B).

In this way it will be possible, at the and of the installation, make a perfect vertical

and horizontal regulation of the gear-motor.

The rack “

B108

”( M4 dim. 20x26 mm in PVC to be screwed) which is

Assembly both sides assuring that they will be well fixed as in picture D.

Open completely the gate

Lean the first assemblied bar of rack on the motor pinion and so keep the rack

perfectly on level and unbolt to the gate.

Make advance the gate around 1/2 mt.

Lean the second bar of rack on the pinion and fix to the first one, in the correct place

by the end of the metallic side.

Repeat the same previous procedure for all the lenght of the gate.

As seen as the gate has not to weight on the pinion of the operator , now you should

lower the operator around 1/2 mm intervening on the vertical regulation of itself.

Fix both ends of the rack , the two limit-switches PIC E(b) making them perfectly

embedded on the rack and then fix them using screws parker 3,9x10.

At this moment put the limit switches in opening and closing Fig e (c) on the suitable

limit- switches holders.

Because of the gate has not to impact the mechanical stops that it must be equipped

, regulate the limit switches in order that the little hammer of the micro end-stroke

hits the limit switch when the gate is some centimeters before the complete closing

or opening.

•

The batteries should be put with industril waste and not with domestic refuse .

(

Law n. 475/88

)

.

ENGLISH

Содержание ROLLER CAT 5

Страница 5: ...1 2 CREMAGLIERA B108 B108 SLITTINO FINECORSA CANCELLO PORTA SLITTINO FINECORSA 3 A B C a b c...

Страница 11: ......