Maintenance manual Universal-1000

P R O M E T A L

80

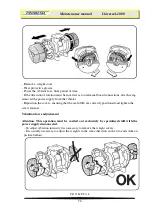

Hopper maintenance

Check condition of

hydraulic cylnder and

bearings regulary! Clean

if needed and lubricate

according to plan (use

only

high quality grease).

Clean hopper by knocking off residual concrete. After this, open hopper outlets to enable the

loose concrete to drop into filler boxes with which the concrete is moved into mould and

removed from the machine together with the pallet.

Check all fixation screws.

Содержание UNIVERSAL 1000

Страница 19: ...Maintenance manual Universal 1000 P R O M E T A L 19 ...

Страница 25: ...Maintenance manual Universal 1000 P R O M E T A L 25 Hydraulic system ...

Страница 26: ...Maintenance manual Universal 1000 P R O M E T A L 26 ...

Страница 27: ...Maintenance manual Universal 1000 P R O M E T A L 27 Basic principles for the installation of hose assemblies ...

Страница 51: ...Maintenance manual Universal 1000 P R O M E T A L 51 This is followed with unscrewing all screws ...

Страница 52: ...Maintenance manual Universal 1000 P R O M E T A L 52 Now lower down tamper head and mould ...

Страница 53: ...Maintenance manual Universal 1000 P R O M E T A L 53 Pull out cart with mould on itself ...

Страница 58: ...Maintenance manual Universal 1000 P R O M E T A L 58 After adjustment is done ...

Страница 65: ...Maintenance manual Universal 1000 P R O M E T A L 65 Vibrator table maintenance ...