Maintenance manual Universal-1000

P R O M E T A L

66

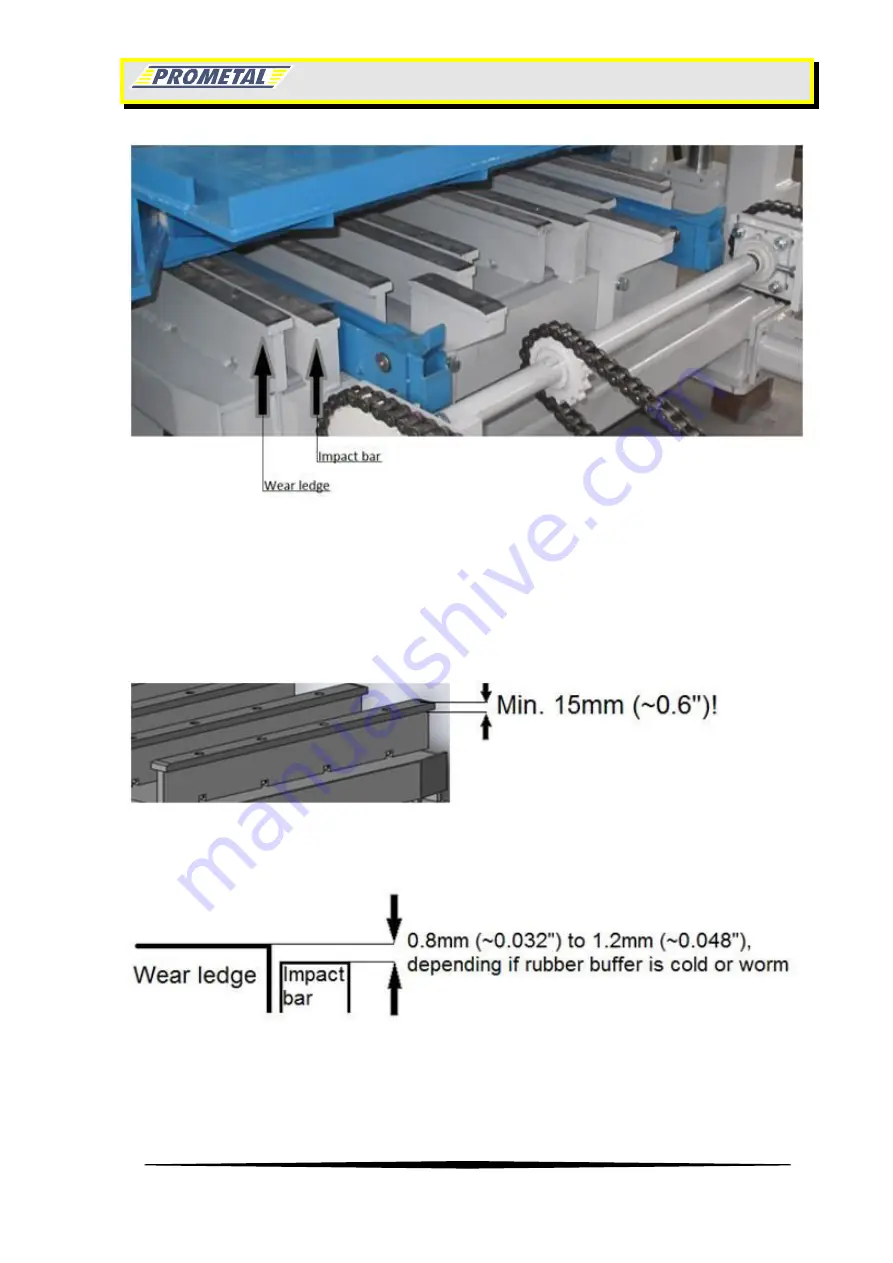

Wear ledges and impact bars

Check the thickness of the wear ledges weekly (every 50h) - minimum = 15mm (~ 0.600

”

)

We recommend changing the wear ledges at a thickness from < 17mm (0.670

”

)! But atleast at

a thickness of 15 mm (0.590

”

) the wear ledges must be changed, otherwise the heads of the

fixation screws will be worn so much, that they can not be removed anymore!

Remove possible paint from the bearing surface, when changing them!

Check weekly (every 50hours) distance and parallelism between wear ledges and the impact

bars. But at least at every mold change!

The right height distance between wear ledges and impact bars must be maintained!

The parallelism over the total surface is

very

important!

Содержание UNIVERSAL 1000

Страница 19: ...Maintenance manual Universal 1000 P R O M E T A L 19 ...

Страница 25: ...Maintenance manual Universal 1000 P R O M E T A L 25 Hydraulic system ...

Страница 26: ...Maintenance manual Universal 1000 P R O M E T A L 26 ...

Страница 27: ...Maintenance manual Universal 1000 P R O M E T A L 27 Basic principles for the installation of hose assemblies ...

Страница 51: ...Maintenance manual Universal 1000 P R O M E T A L 51 This is followed with unscrewing all screws ...

Страница 52: ...Maintenance manual Universal 1000 P R O M E T A L 52 Now lower down tamper head and mould ...

Страница 53: ...Maintenance manual Universal 1000 P R O M E T A L 53 Pull out cart with mould on itself ...

Страница 58: ...Maintenance manual Universal 1000 P R O M E T A L 58 After adjustment is done ...

Страница 65: ...Maintenance manual Universal 1000 P R O M E T A L 65 Vibrator table maintenance ...