Maintenance manual Universal-1000

P R O M E T A L

67

-

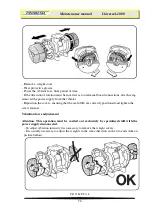

Clean all wear ledges and impact bars properly, before You start

adjusting them

-

Unlock all fixation screws on the vibrator table; on every vibrator table

open the screws at least 2 turnes

-

Open the lock nut on the adjusting screw for the wegde type hight

adjuster

-

Place a ruler across the wear ledges and measure the distance between

wear ledges and impact bars (measure distance equally outer side of the

vibrator table)

-

Adjust the exact dimension by turning adjusting screw to the right (or

left). Repeat this process on every adjusting screw

-

Secure this setting with lock nut on adjusting screw

-

Tighten fixation screws with 710 Nm (every thread

must

be greased

only

with high quality grease), use

only

torque wrench

Содержание UNIVERSAL 1000

Страница 19: ...Maintenance manual Universal 1000 P R O M E T A L 19 ...

Страница 25: ...Maintenance manual Universal 1000 P R O M E T A L 25 Hydraulic system ...

Страница 26: ...Maintenance manual Universal 1000 P R O M E T A L 26 ...

Страница 27: ...Maintenance manual Universal 1000 P R O M E T A L 27 Basic principles for the installation of hose assemblies ...

Страница 51: ...Maintenance manual Universal 1000 P R O M E T A L 51 This is followed with unscrewing all screws ...

Страница 52: ...Maintenance manual Universal 1000 P R O M E T A L 52 Now lower down tamper head and mould ...

Страница 53: ...Maintenance manual Universal 1000 P R O M E T A L 53 Pull out cart with mould on itself ...

Страница 58: ...Maintenance manual Universal 1000 P R O M E T A L 58 After adjustment is done ...

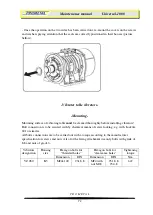

Страница 65: ...Maintenance manual Universal 1000 P R O M E T A L 65 Vibrator table maintenance ...