Usage instructions SPEEDY F4 & F2

56

Settings on the brake could be necessary for

the following reasons:

You have changed the tyre or the tyre

pressure.

You have changed the wheel tracking or

the position of the drive wheels.

The brake is pulling unevenly or insuffi-

ciently after extended use.

To adjust the integrated brake, proceed as

follows on both sides:

1. Initial situation: Drive wheels mounted on

the product and the integral brakes open.

The drive wheels have the specified infla-

tion pressure.

2. Undo the M5 clamp screws (AF 4 mm)

slightly so that the integral brake can be

pushed in the welded-on bracket with the

splined shaft.

Figure 164: Description overview of the integrated

brake (product view from below)

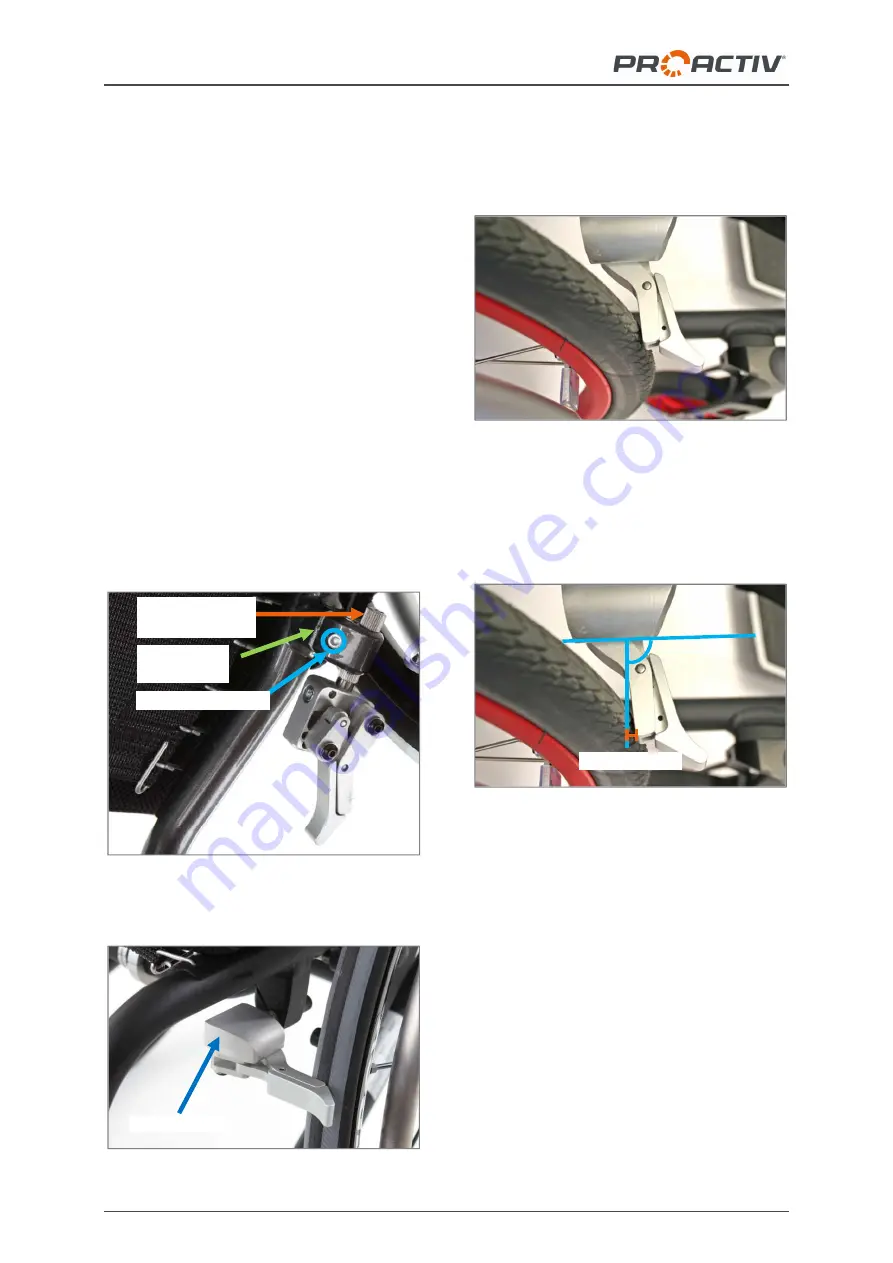

Figure 165: Brake mount

3. Press the front part of the control element

to the right or left outwards until the brake

element rests against the tyre. Do not

close the brake completely.

Figure 166: Brake element resting on the tyre

4. Slide the integral brake with the splined

shaft in the welded-on bracket so that the

braking element is positioned as shown in

the following figure:

Figure 167: Brake element after correct positioning

of the integral brake

5. Tighten up the M5 clamp screw (AF 4 mm)

again to 4 Nm.

6. Then check the correct setting of the

brakes: On a slope (7° gradient) the prod-

uct should stand firm with the brake ap-

plied. This will happen if, with the brake

closed, the tyre is depressed or deformed

by approximately 4 mm by the brake ele-

ment (at prescribed air pressure in the

tyres).

•

approx. 4 mm

Brake mount

M5 clamp screws

Welded-on

bracket

Integral splined

shaft