Usage instructions SPEEDY F4 & F2

48

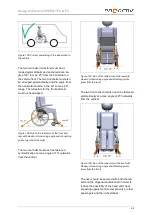

Figure 134: Central anti-tipping support removed

Figure 135: Fixing shells on the rear frame cross

section

Figure 136: Centring half shells on the front frame

cross bar

24.3 Safety instructions

The anti-tipping support is designed ex-

clusively to minimise the risk of tipping over

backwards. It is not suitable for reducing the

risk of tipping forwards or to the side. There is

no safety equipment on offer for minimizing

these risks. For this reason, handling these

risks need to be learnt in cooperation with your

therapists and doctors.

Before using the product, each time after

loading the anti-tipping supports and after eve-

ry adjustment to the product, make sure that

the anti-tipping supports are fully functional. In

this case, it must not be possible to swivel the

anti-tipping supports to the side when in oper-

ating position without having to unlock them

first.

The lower edge of the anti-tipping wheels

may not be more than 5

cm from the ground. If

a larger gap is required or necessary, then you

need to work with your therapists and doctors

to practice and learn to handle the increased

risk of tipping.

If the functionality of the anti-tipping sup-

ports is no longer ensured or if you are in any

doubt about their flawless function, have them

checked by your rehabilitation specialist dealer

and repaired before any further use. Otherwise

there is an increased risk or falling of getting

injured.

25 Brakes

25.1 Knee lever brake

25.1.1 Opening and closing the brake

The knee lever brake can be equipped with

different brake levers, such as, e.g. standard

brake lever, long brake lever, flared brake lever

and flip-down brake handle. The brake lever

can be mounted in the standard position, or

low. However, operation is identical for all of

these brake levers.

Figure 137: Knee lever brake system with standard

brake lever

Centring half shells

Fixing shells

Clamping bracket with clamp levers

and fixing hooks

Fixing hooks of the anti-tipping support