Packaged Glycol Chiller Systems |

III

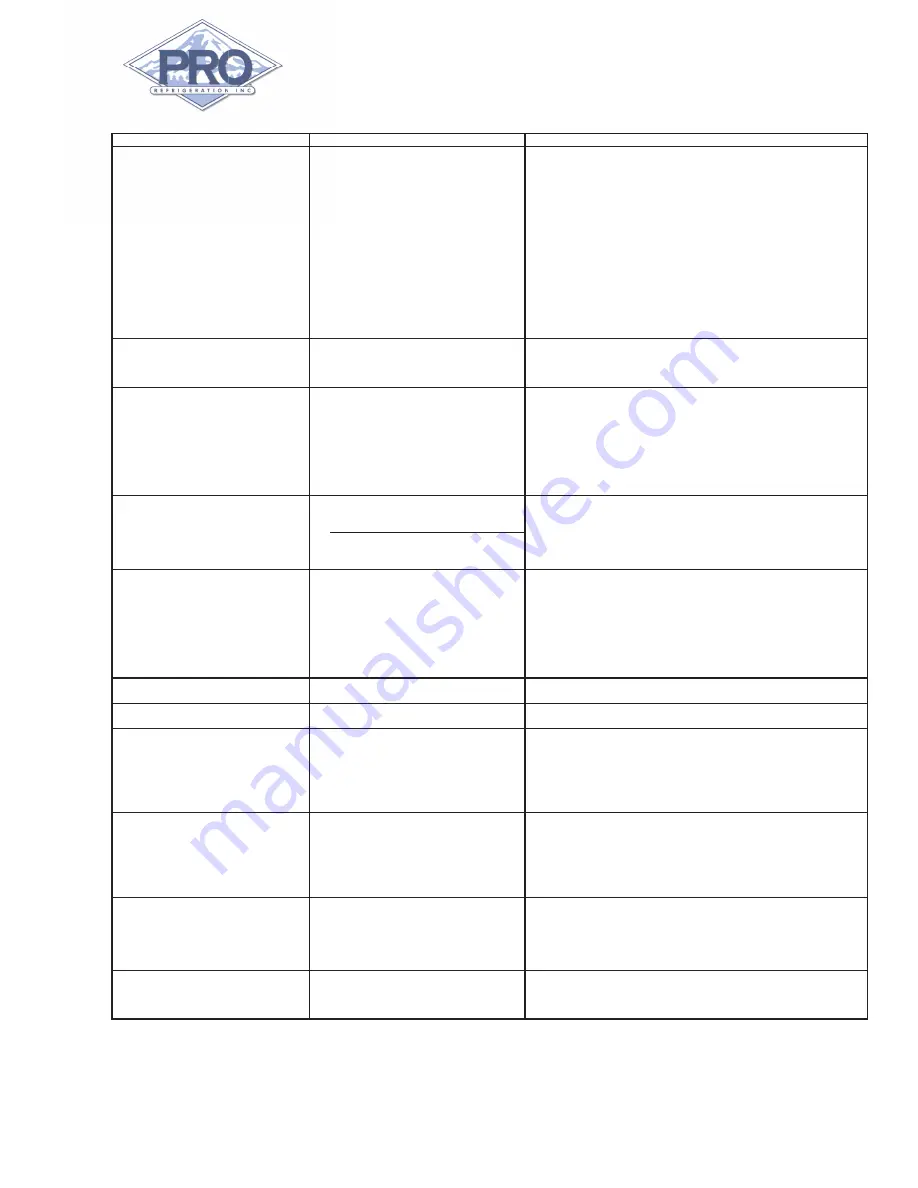

PROBLEM

POSSIBLE CAUSES

CORRECTIVE STEPS

compressor will not run

A

Main Switch / Circuit Breaker Open

A

Reset Switch / Circuit Breaker

B

Fuse Blown

B

Check Electrical Circuits and Motor Windings

C

Thermal Overloads Tripped

for shorts or grounds. Investigate for possible over-

D

Defective Contactor or Coil

loading. Replace Fuse or reset Circuit Breaker after

E

System shut down by Safety Device

fault is corrected.

F

No Cooling is required

C

Reset any tripped thermal overloads, Check unit

G

Liquid Line solenoid will not open

closely when unit comes online.

H

Motor Electrical Trouble

D

Repair or replace coil

I

Loose Wiring

E

Determine Type and Cause of shut down and

J

Circulation Pump Not Running

correct before resetting.

F

Wait until Unit calls for Cooling. Check setting of

Thermostat. Check the Temperature of Glycol Solution.

G

Check for Voltage at Solenoid Coil, replace coil.

H

Check motor for opens, short circuit, or burnout.

I

Check all wire junctions, tighten loose connections.

J

Check overload relay on circulation Pump

Compressor noisy or vibrating

A

Liquid Refrigerant Flooding to Crankcase

A

Check Superheat Setting of Expansion Valve(s).

B

Worn Compressor

Check the Glycol Solution Percentage, make

certain that evaporator is not freezing up.

B

Replace Compressor

High Discharge Pressure

A

Condenser Water Supply is insufficient or

A

Adjust Water Regulating Valve, investigate ways to

temperature is too high.

increase water supply.

B

Fouled Condenser (Water)

B

clean

Fouled Cooling Tower

C

Purge out non-condensables, reclaim refrigerant

Dirty Condenser Fin or Tube Surface (Air)

and recharge with new refrigerant.

C

Non-Condensables in System

D

Remove excess refrigerant charge

D

System overcharged with Refrigerant

E

Open Valve

E

Discharge Valve Partially closed

F

Check Condenser Rating Tables

F

High Ambient Conditions

Low Discharge Pressure

A

Faulty Condenser Fan Control

A

Check Fan Controls

B

Suction Shut off partially closed

B

Open Valve

C

C

Adjust Water Regulating Valve or Water Supply

D

D

See "Low Suction Pressure" below

E

Insufficient Refrigerant Charge

E

Check for leaks, repair & recharge

F

Low Ambient Conditions

F

Check Condenser rating tables

Low Suction Pressure

A

Lack of Refrigerant

A

Check for leaks, repair, & recharge.

B

Clogged Liquid Line Filter Drier

B

Replace

C

Expansion Valve malfunction

C

Check Superheat Setting, adjust or replace.

D

Condensing Temperature too low

D

Check means of regulating Condensing Temperature

E

Compressor will not unload

E

See "Compressor will not unload" section below

F

Insufficient Flow through evaporator

F

Check circulation pump rotation and motor amperage.

G

Not enough Glycol Concentration or Glycol

Make sure Gate Valves on Evaporator inlet & outlet

Level in Tank is too Low.

are completely open.

7-5

G

Add required Glycol to System

High Suction Pressure

A

Excessive Load

A

Reduce Load or add additional cooling equipment

B

Expansion Valve malfunction

B

Check Superheat of TXV, replace if necessary

Compressor will not unload

A

Unloader mechanism defective

A

Replace mechanism

B

Faulty Thermostat or Pressure Control

B

Check settings of device, replace if necessary

Oil Alarm

A

Excessive Liquid Refrigerant in crankcase

A

Check crankcase Heater. Adjust TXV superheat.

B

Oil Failure Control defective

B

Replace

C

Worn Oil Pump

C

Replace Oil Pump.

D

Stuck reversing gear on oil pump

D

Reverse Rotation of Compressor

E

Worn Bearings

E

Replace Compressor

F

Low Oil Level

F

Check System for leaks, repair, & add Oil.

G

Pump Housing Gasket leaks

G

Replace Gasket

Motor Overload Fault, tripped Circuit

A

Low Voltage during high load conditions

A

Check for excessive voltage drop

Breaker, or Blown Fuses

B

Grounded wiring in motor or power circuit

B

Check wiring and repair fault.

C

Loose power wiring

C

Check wiring and tighten any loose connections

D

High Condensing Pressure

D

See corrective steps for "High Discharge Pressure"

E

Voltage unbalance

E

Check Power Supply. Contact Power Company. Do not

F

High Ambient at bi-metal Overload Relay

Operate until fault is corrected.

F

Provide Ventilation to Motor Controls

Compressor Thermal Switch Open

A

Operating out of design conditions

A

Add facilities to prevent system from operating out of

B

Discharge Valve Partially closed

design conditions.

C

Blown Valve Plate Gasket

B

Open

D

Power Line Fault

C

Replace Gasket

D

Check Power Supply. Contact Power Company. Do not

Operate until fault is corrected.

Low Pressure Freeze Alarm

A

Wrong Pump Rotation

A

Reverse Rotation of circulation pump (CW from motor end)

B

Evaporator Freeze Up

B

Check Glycol Percentage. Must be at least 20 F below

C

Incorrect Freeze Point setpoint

thermostat set point.

C

Adjust freeze point for application, consult factory.

Содержание CHILSTAR Series

Страница 1: ...Operations Manual...

Страница 7: ...Packaged Glycol Chiller Systems 5 3ST Series Pump Curve 5SH Series Pump Curve...

Страница 24: ...Packaged Glycol Chiller Systems V NOTES...