A4. OPERATING PROCEDURES

69

Lifting and Placing Loads (continued)

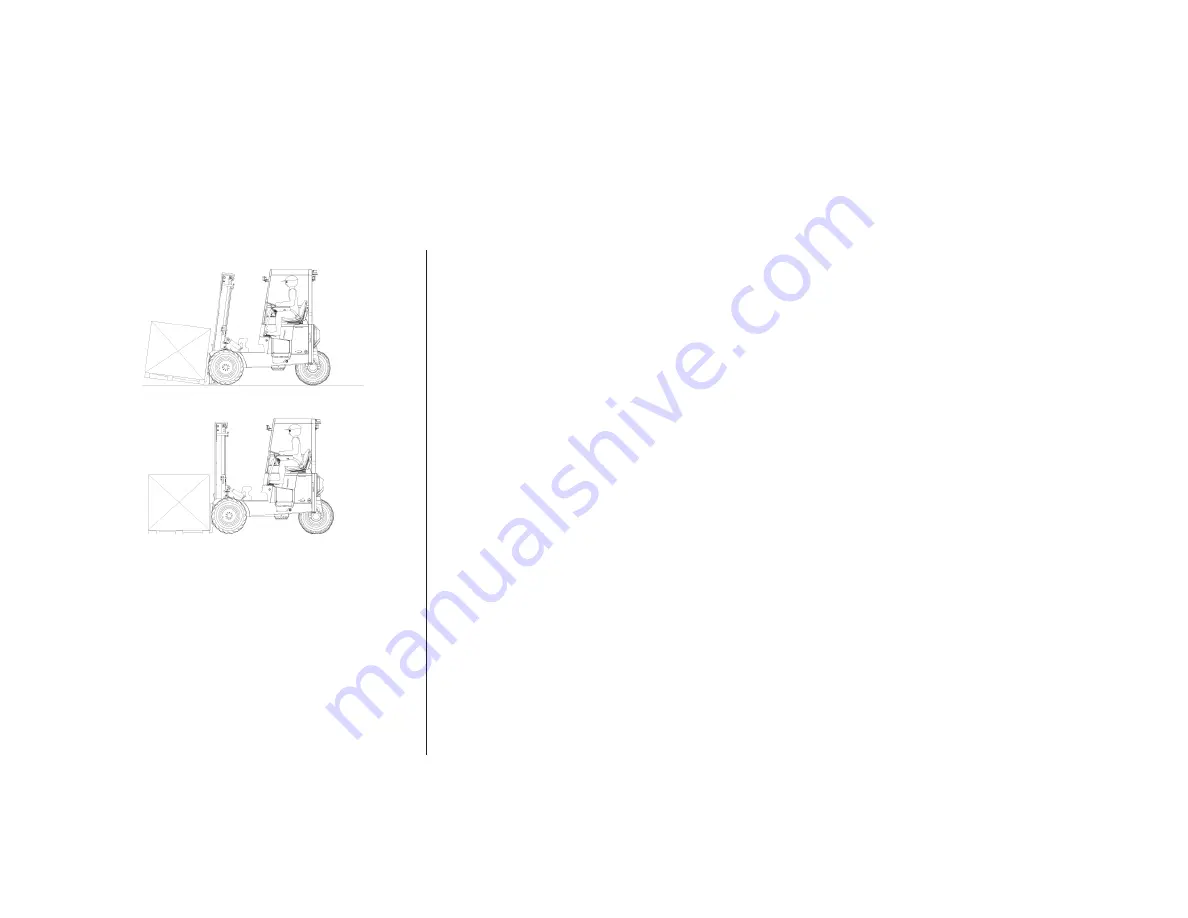

Placing a Cubed Load at Ground Level

1. Check the area and be certain that the load can be safely placed.

2. Approach the placement area squarely.

3. Check that the surface is strong enough to support the stabilizers. If not,

place a metal or wooden support underneath which is strong enough to

support the stabilizers.

4. Lower the stabilizers fully.

5. Extend the mast fully.

6. Lower the forks to the ground.

7. Tilt the mast forward slightly to deposit the load.

8. Raise the stabilizers fully.

9. Back up carefully until the forks are clear of the load.

10. Slowly drive away looking in the direction of travel, keeping the mast

extended fully.

Содержание Truck Mounted Forklift

Страница 2: ...25 1 16758 7 216...

Страница 30: ...A2 INTRODUCTION 22 Safety Decals continued Part Number 517 230 0003...

Страница 31: ...A2 INTRODUCTION 23 Safety Decals continued Part Number 517 130 0003...

Страница 33: ...A2 INTRODUCTION 25 Safety Decals continued Part Number 517 100 0086 Part Number 517 100 0141...

Страница 35: ...A2 INTRODUCTION 27 Safety Decals continued Part N o USA018 Part N o 517 230 0008...

Страница 37: ...A2 INTRODUCTION 29 Safety Decals continued Part N umber ENG019 Part N umber 517 999 0254...

Страница 41: ...A2 INTRODUCTION 33 Safety Decals continued...

Страница 44: ...A2 INTRODUCTION 36 Instruments and Controls continued...

Страница 127: ...A6 MAINTENANCE 119 Grease Point Chart continued...

Страница 128: ...A6 MAINTENANCE 120 Grease Point Chart continued Steering Linkage Spindle Housing and Steering Cylinder Grease Point...

Страница 129: ...A6 MAINTENANCE 121 Grease Point Chart continued FEM 2 Fork Carriage Grease Points...

Страница 130: ...A6 MAINTENANCE 122 Grease Point Chart continued FEM 3 Fork Carriage Grease Points...

Страница 131: ...A6 MAINTENANCE 123 Grease Point Chart continued Chain Rollers Grease Points...

Страница 132: ...A6 MAINTENANCE 124 Grease Point Chart continued Mast Section Grease Points...

Страница 133: ...A6 MAINTENANCE 125 Grease Point Chart continued Tilt Cylinder Grease Points...

Страница 134: ...A6 MAINTENANCE 126 Grease Point Chart continued Side Shift Cylinder Grease Points...

Страница 135: ...A6 MAINTENANCE 127 Grease Point Chart continued Mast Carriage Grease Points...

Страница 136: ...A6 MAINTENANCE 128 Grease Point Chart continued Side Shift Bushing Grease Points...

Страница 137: ...A6 MAINTENANCE 129 Grease Point Chart continued Lift Cylinder Grease Points...

Страница 154: ......

Страница 160: ...1752 8 7 21 3 172 5 3 6DIHW HFDOV FRQWLQXHG 3DUW 1R...

Страница 161: ...1752 8 7 21 3 172 5 3 6DIHW HFDOV FRQWLQXHG...

Страница 164: ...1752 8 7 21 3 172 5 3 GUDXOLF HYHUV FRQWLQXHG...

Страница 173: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG...

Страница 174: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG LIW OLQGHU UHDVH 3RLQWV...

Страница 175: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG 0DVW 2XWHU 6HFWLRQ UHDVH 3RLQWV WHP WHP WHP WHP...

Страница 176: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG 0DVW QQHU 6HFWLRQ UHDVH 3RLQWV...

Страница 177: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG 3DQWRJUDSK 0DVW 6HFWLRQ UHDVH 3RLQWV WHP WHP WHP WHP...

Страница 178: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG 3DQWRJUDSK UP 0LGGOH 6HFWLRQ UHDVH 3RLQWV...

Страница 179: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG 3DQWRJUDSK UP 5HDU 6HFWLRQ UHDVH 3RLQWV...

Страница 180: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG 3DQWRJUDSK UP URQW 6HFWLRQ UHDVH 3RLQWV...

Страница 181: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG 3DQWRJUDSK OLQGHU UHDVH 3RLQWV WHP...

Страница 182: ......

Страница 184: ......

Страница 185: ...Machine Model Serial Number Capacity Customer Name Customer Address Date DEALER S STAMP...

Страница 190: ...C2 RECORD OF DAMAGE 182 Date Name Brief Details of Damage or Accident Job No Reported to...

Страница 191: ...C3 RECORD OF TRANSFER OF FORKLIFT 183 Date Transferred From Comments Transport No Transferred to...

Страница 192: ...C4 Notes 184...