A4. OPERATING PROCEDURES

58

Driving Techniques (continued)

Parking

Always park the Truck Mounted Forklift in a designated

safe area. Apply the park brake. Lower the forks fully to

the ground. Neutralize all controls. Switch off the

ignition and remove the key. Chock the wheels if the

vehicle is on uneven ground.

If parking on an incline, point the machine uphill, chock

the front wheels and turn the rear wheel across the

incline.

Note:

For machines equipped with a brake on the rear

hub, it is recommended that the stabilizers be lowered

when parking the machine on an incline.

Park Brake Test

As part of the daily checks it is important to ensure that

the machines park brake is working correctly. To check

this, place rated load on the forks and drive the forklift

on to a 15% incline. Apply the parking brake and set

the forward/reverse pedal in the neutral position. The

forklift should not move. Ensure no personnel are near

the machine while carrying out this test.

Note:

IF A FAULT IS DETECTED DURING THE PARK

BRAKE TEST, TAKE THE FORKLIFT OUT OF SERVICE,

NOTIFY YOUR SUPERVISOR AND HAVE IT INSPECTED

AND REPAIRED.

Operating On Inclines

The Truck Mounted Forklift is intended for use on firm,

flat and stable surfaces. AVOID slopes and uneven or

unstable surfaces where possible. However, when a job

site conditions involve slopes, inclines or rough terrain,

you must take additional care when operating the

machine.

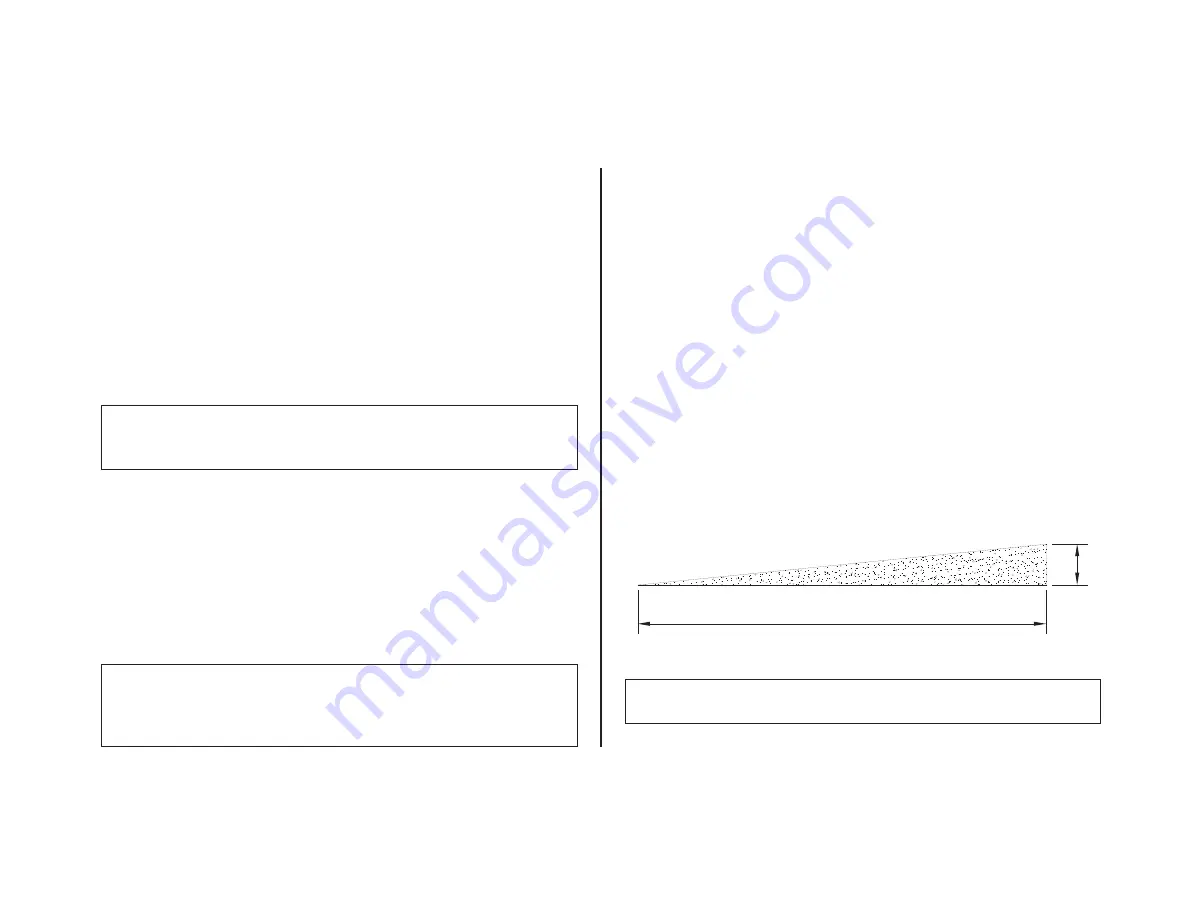

Grades

The grade of an incline is measured as the number of

feet a surface rises or falls over a horizontal distance

and is expressed as a percentage.

In the example shown below, the incline rises a height

H over a horizontal distance L. This results in the incline

having a grade of (H/L) * 100%.

Note:

Ground conditions and terrain may affect the

forklifts ability to operate on these inclines.

INCLINE GRADE = (H/L) * 100%

L

H

Содержание Truck Mounted Forklift

Страница 2: ...25 1 16758 7 216...

Страница 30: ...A2 INTRODUCTION 22 Safety Decals continued Part Number 517 230 0003...

Страница 31: ...A2 INTRODUCTION 23 Safety Decals continued Part Number 517 130 0003...

Страница 33: ...A2 INTRODUCTION 25 Safety Decals continued Part Number 517 100 0086 Part Number 517 100 0141...

Страница 35: ...A2 INTRODUCTION 27 Safety Decals continued Part N o USA018 Part N o 517 230 0008...

Страница 37: ...A2 INTRODUCTION 29 Safety Decals continued Part N umber ENG019 Part N umber 517 999 0254...

Страница 41: ...A2 INTRODUCTION 33 Safety Decals continued...

Страница 44: ...A2 INTRODUCTION 36 Instruments and Controls continued...

Страница 127: ...A6 MAINTENANCE 119 Grease Point Chart continued...

Страница 128: ...A6 MAINTENANCE 120 Grease Point Chart continued Steering Linkage Spindle Housing and Steering Cylinder Grease Point...

Страница 129: ...A6 MAINTENANCE 121 Grease Point Chart continued FEM 2 Fork Carriage Grease Points...

Страница 130: ...A6 MAINTENANCE 122 Grease Point Chart continued FEM 3 Fork Carriage Grease Points...

Страница 131: ...A6 MAINTENANCE 123 Grease Point Chart continued Chain Rollers Grease Points...

Страница 132: ...A6 MAINTENANCE 124 Grease Point Chart continued Mast Section Grease Points...

Страница 133: ...A6 MAINTENANCE 125 Grease Point Chart continued Tilt Cylinder Grease Points...

Страница 134: ...A6 MAINTENANCE 126 Grease Point Chart continued Side Shift Cylinder Grease Points...

Страница 135: ...A6 MAINTENANCE 127 Grease Point Chart continued Mast Carriage Grease Points...

Страница 136: ...A6 MAINTENANCE 128 Grease Point Chart continued Side Shift Bushing Grease Points...

Страница 137: ...A6 MAINTENANCE 129 Grease Point Chart continued Lift Cylinder Grease Points...

Страница 154: ......

Страница 160: ...1752 8 7 21 3 172 5 3 6DIHW HFDOV FRQWLQXHG 3DUW 1R...

Страница 161: ...1752 8 7 21 3 172 5 3 6DIHW HFDOV FRQWLQXHG...

Страница 164: ...1752 8 7 21 3 172 5 3 GUDXOLF HYHUV FRQWLQXHG...

Страница 173: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG...

Страница 174: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG LIW OLQGHU UHDVH 3RLQWV...

Страница 175: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG 0DVW 2XWHU 6HFWLRQ UHDVH 3RLQWV WHP WHP WHP WHP...

Страница 176: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG 0DVW QQHU 6HFWLRQ UHDVH 3RLQWV...

Страница 177: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG 3DQWRJUDSK 0DVW 6HFWLRQ UHDVH 3RLQWV WHP WHP WHP WHP...

Страница 178: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG 3DQWRJUDSK UP 0LGGOH 6HFWLRQ UHDVH 3RLQWV...

Страница 179: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG 3DQWRJUDSK UP 5HDU 6HFWLRQ UHDVH 3RLQWV...

Страница 180: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG 3DQWRJUDSK UP URQW 6HFWLRQ UHDVH 3RLQWV...

Страница 181: ...0 17 1 1 3 172 5 3 UHDVH 3RLQWV FRQWLQXHG 3DQWRJUDSK OLQGHU UHDVH 3RLQWV WHP...

Страница 182: ......

Страница 184: ......

Страница 185: ...Machine Model Serial Number Capacity Customer Name Customer Address Date DEALER S STAMP...

Страница 190: ...C2 RECORD OF DAMAGE 182 Date Name Brief Details of Damage or Accident Job No Reported to...

Страница 191: ...C3 RECORD OF TRANSFER OF FORKLIFT 183 Date Transferred From Comments Transport No Transferred to...

Страница 192: ...C4 Notes 184...