Monthly Task

Instruction

Vacuum debris from

around motor, pulleys, and

floor underneath the tread-

mill

1

.

Remove hood. Use a vacuum cleaner (recommended with

static protection feature) to clean debris and lint from front

area under the front cover. Be careful not to bring the nozzle

to close to any electronic circuit boards.

Clean and lubricate the lift

motor jackscrew (Inline

models only).

Clean and lubricate the lift motor jackscrew with an

approved grease, see

"General Information" on page 3

Inspect visible welds,

frame, and wire con-

nections

1

.

Do a visual check of welds and frame. Check for loose wire

connections.

Perform the Operation

Verification tests to verify

machine features and oper-

ation.

Do the Operation verification procedure and return to ser-

vice, see

"Operation Verification" on page 15

.

Quarterly Maintenance

Perform the following maintenance tasks every 3 months:

Quarterly Task

Instruction

Verify the running belt tension,

alignment, and tracking.

Verify the running belt tension, alignment and tracking,

see "Running Belt Adjustment" procedure.

Verify the Drive Motor belt tension. Verify the Drive Motor belt tension and adjust as neces-

sary, see "Drive Motor Belt Tension Adjustment" pro-

cedure.

Vacuum the front compartment

and Motor Controller fan.

Remove hood and vacuum the compartment and Motor

Controller fan. It is recommended that you use a static

resistant vacuum cleaner. Be careful to not put nozzle

near PCA electronics.

Check the console metric and

indicator display and numeric

keypad functionality.

Run the Display\Keypad diagnostic tests and check the

console metric/indicator LED/LCD displays and numeric

keypad functionality. On P82 series touch-screen con-

soles, run the Touchscreen/Backlight/RGB/Numeric

Backlight/Numeric Display diagnostic tests, refer to

"Hardware Validation Service Mode (51765761)" on

page 21

Record the current Odometer and

Hours.

Access the Information Display or Equipment Usage

data and record the Odometer and Hours metrics, see,

"Information Display (65)" on page 33

Note: 1). Perform task with power removed and incline set to maximum level.

2) Diagnostic Test will vary depending on console model.

Semi-Annual Maintenance

Experience Series 700 Line Treadmills

155

7 Preventative Maintenance

Maintenance Schedule

Содержание Experience TRM700-16

Страница 1: ...Service Manual Experience Series 700 line TRM700 16 Base Treadmill 120 VAC and 240 VAC ...

Страница 19: ...Experience Series 700 Line Treadmills 12 1 Introduction General Information ...

Страница 62: ...Experience Series 700 Line Treadmills 55 5 Replacement Procedures Covers and Panels Replacement ...

Страница 94: ...Experience Series 700 Line Treadmills 87 5 Replacement Procedures Motor Controller MC Replacement ...

Страница 104: ...Experience Series 700 Line Treadmills 97 5 Replacement Procedures Drive Belt Replacement ...

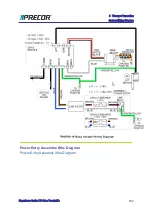

Страница 172: ...Experience Series 700 Line Treadmills 165 8 Theory of Operation System Wiring Diagram ...

Страница 174: ...Experience Series 700 Line Treadmills 167 8 Theory of Operation Exploded View Diagram ...

Страница 175: ...Experience Series 700 Line Treadmills 168 8 Theory of Operation Exploded View Diagram ...

Страница 176: ...Experience Series 700 Line Treadmills 169 8 Theory of Operation Exploded View Diagram ...

Страница 177: ...Experience Series 700 Line Treadmills 170 8 Theory of Operation Exploded View Diagram ...

Страница 178: ...Experience Series 700 Line Treadmills 171 8 Theory of Operation Exploded View Diagram ...

Страница 179: ...Experience Series 700 Line Treadmills 172 8 Theory of Operation Exploded View Diagram ...

Страница 181: ...Experience Series 700 Line Treadmills 174 8 Theory of Operation Parts List ...

Страница 182: ...Experience Series 700 Line Treadmills 175 8 Theory of Operation Parts List ...

Страница 183: ...Experience Series 700 Line Treadmills 176 8 Theory of Operation Parts List ...