3-1/2", 28° Framing Nailer

11

For technical questions call: 1-800-665-8685

8314106

V 2.0

RECOMMENDED HOOK UP

Minimum components required for hookup

Air compressor: The air compressor must be able to maintain a minimum of 70 PSI when the nailer is being used.

An inadequate air supply can cause a loss of power and inconsistent driving.

Pressure regulator: A pressure regulator is required to control the operating pressure of the nailer between

70 PSI and 115 PSI.

Air supply hose: Always use air supply hoses with a minimum working pressure rating equal to or greater than the

pressure from the power source, or 150 PSI, whichever is greater. Use 1/4" air hose for runs up to 50 feet. Use

3/8" air hose for 50 feet, run or longer.

HOOK UP INSTRUCTIONS FOR TOOL TO AIR SUPPLY

Note: For better performance, install a 3/8 inch quick plug(1/4inch NPT threads) with an inside diameter of 0.315

inch (8mm) on the nailer and a 3/8 inch quick coupler on the air hose.

1. With ON/OFF switch in OFF position, plug compressor into electrical outlet.

2. Close pressure regulator by turning all the way to the left. Turn compressor ON and let it pump all the way up

to automatic shut-off pressure.

3. Attach air hose to regulator outlet. Adjust pressure regulator by turning to the right so that outlet pressure is

between 70 PSI to115 PSI.

4. Load fasteners into nailer.

5. Point the nailer in a safe direction while attaching to air hose.

6. Nailer is ready for use. You may need to adjust outlet pressure to achieve proper fastener depth.

MAINTENANCE

JAM CLEARING

If a nail becomes jammed in the tool, disconnect the air hose and keep the tool pointed away from you while

clearing the jam.

1. Disconnect the tool from the air supply.

2. Remove nails from the tool.

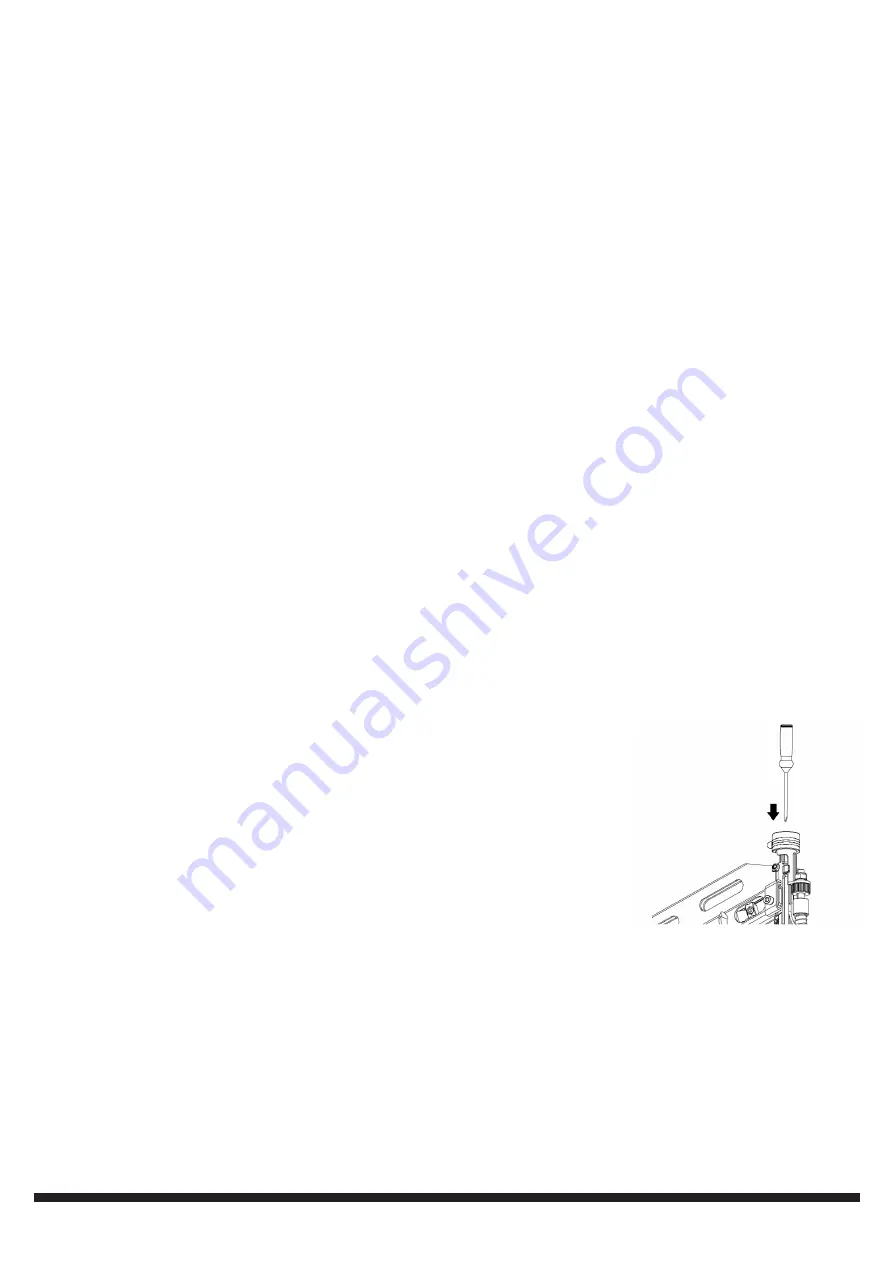

3. Insert screwdriver into the driving mechanism.

4. Tap the screwdriver gently with a hammer. The inserted screwdriver should

push the driver blade back, freeing the nail jam.

5. Remove the bent nail, using needle-nose pliers if necessary.

6. Reconnect the tool to the air supply.

7. Reload the tool with nails.

CLEANING

WARNING! When cleaning a tool be careful not to disassembly any portion of the tool since internal components

may be misplaced or safety components may be improperly mounted. Certain cleaning agents such as gasoline,

carbon tetrachloride, ammonia. etc. may damage plastic parts and o-rings.

WARNING! Do not attempt to clean by inserting pointed objects through openings. Sharp edges may damage

internal components causing a serious hazard. Ventilation openings, the work contact element, and the trigger

must be kept clean and free of foreign matter. Periodically clean the tool with compressed air. Clean the

magazine. Remove metal or wooden chips which may have accumulated in the magazine. Periodically clean

magazine with compressed air.

Содержание 8314106

Страница 2: ......

Страница 15: ...3 1 2 28 Framing Nailer 15 For technical questions call 1 800 665 8685 8314106 V 2 0...

Страница 16: ......

Страница 18: ......