3

Scroll Enclosure Air Compressors

General Safety Information

The

operator

of this compressor

must

take the necessary

precautions to prevent the level of danger indicated by these

symbols. The operator is also required to read and understand

this instruction manual and all safety warnings, labels, etc.

Any

employer

allowing the use of this compressor in their

fi eld of work

must

distribute this instruction manual to

all users. The employer must also ensure all users read,

understand and follow the instructions as described in the

manual, safety warnings, labels, etc.

1. Read and understand all safety warnings and

instructions before operating this compressor.

Failure to read and follow all safety warnings

may result in serious personal injury or death.

Property damage and/or compressor damage

may also occur if all warnings are not followed.

2. Air used for breathing or food processing must

meet O.S.H.A. 29 C.F.R. 1910.134 or C.F.R. 178.3570

regulations.

Motors,

electrical

equipment and

controls can cause electrical arcs that will ignite a

fl ammable gas or vapor. Never operate or repair in

or near a fl ammable gas or vapor. Never store

fl ammable liquids or gases in the vicinity of the compressor.

3. Safety Valves or Relief Valves used on this compressor

must be in accordance with ANSI/ASME B19 safety

standards. Improperly sized Safety Valves will result in

serious personal injury or death.

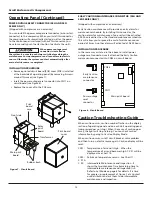

Do not remove the

panel or try to

service the air compressor while the compressor is

running or while the air receiver is under pressure.

Serious personal injury or death will occur.

4. Never use rubber hoses, plastic piping or soldered joints

in any part of the compressed air or gas system. The

compressor and system piping must be compatible.

5. The compressor will shutoff when the pressure reaches a

predetermined maximum pressure. Care should be used

since the compressor may suddenly restart automatically

when the pressure drops to the predetermined minimum

pressure. Never assume the compressor is ready for

service just because the unit is stopped.

Release

all

pressure

from the system

before attempting to install, service, relocate or

perform any maintenance.

6. Keep clear of all moving parts especially if the compressor

is operating with the door panel removed for inspection

or repair.

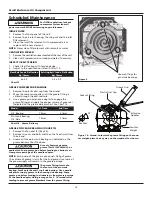

Do not touch HOT

parts of the

compressor such as the air end, discharge pipe,

aftercooler, motor, etc.

7. Keep

fl ammable gases away from the compressor. Parts

of the compressor become very hot during operation and

the vapors from fl ammable gases may cause the unit to

explode.

8. Never use fl ammable or toxic solvents to clean the

compressor or any of the unit’s parts.

9. Do not remove or tamper with any safety devices,

guards, panels or insulation parts while compressor is in

operation. All guards or panels must be in place before

starting or operating the compressor.

Install a properly

sized Safety Relief

Valve in the discharge piping ahead of or before

a shut-off valve, heat exchanger, orifi ce, etc. The

compressor or part of the system could rupture or

explode if a Safety Relief Valve is not installed.

10. Do not change the pressure setting of the Safety Relief

Valve. Do not replace the Safety Relief Valve with a plug

or restrict the Safety Relief Valve. The system or the

compressor may be over-pressurized if the Safety Relief

Valve is tampered with in any way.

11. Do not service the compressor or any compressor part

while the unit is in operation.

12. Do not remove, disconnect or tamper with the High

Temperature Shutdown Switch. The High Temperature

Shutdown Switch must be installed on the compressor

to protect against high temperatures damaging the

compressor.

13. All electrical connections should be made by a qualifi ed

electrician.

Disconnect

all

power supplies to

the compressor before opening the electrical box

or before servicing the unit. High voltage may be

present.

14. Never remove or alter any safety warning labels, tags,

etc. located on or provided with compressor.

MANUAL

Breathable Air Warning

This compressor / pump is not equipped and should

not be used “as is” to supply breathing quality air. For

any application of air for human consumption, you

must fi t the air compressor / pump with suitable in-line

safety and alarm equipment. This additional equipment

is necessary to properly fi lter and purify the air to

meet minimal specifi cations for Grade D breathing as

described in Compressed Gas Association Commodity

Specifi cation G 7.1 - 1966, OSHA 29 CFR 1910. 134,

and / or Canadian Standards Associations (CSA).

DISCLAIMER OF WARRANTIES

IN THE EVENT THE COMPRESSOR IS USED FOR THE

PURPOSE OF BREATHING AIR APPLICATION AND PROPER

IN-LINE SAFETY AND ALARM EQUIPMENT IS NOT

SIMULTANEOUSLY USED, EXISTING WARRANTIES ARE

VOIDED, AND POWEREX DISCLAIMS ANY LIABILITY

WHATSOEVER FOR ANY LOSS, PERSONAL INJURY OR

DAMAGE.