5

Scroll Enclosure Air Compressors

Installation (Continued)

2) Install the exhaust duct in order to minimize the

pressure lost of the ducting. Keep the distance between

the inlet duct and the compressor exhaust to be at least

12 inches for ease of maintenance. Intake section of the

duct should be larger than the dimension of compressor

exhaust shown below:

WIRING

All electrical hook-ups must be performed by a qualifi ed

electrician. Installations must be in accordance with local and

national electrical codes.

1. Use solderless terminals to connect the electric power

source.

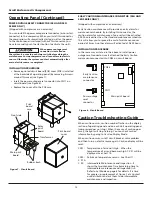

2. Remove front panel.

3. Remove the rectangle electrical box cover located

beneath air inlet fi lter on the right front of the unit.

4. Connect the power inlet cable to the inlet power

junction block located on the inlet side of all starter

connections.

Consult your NEC and local codes for wire size

PIPING

These units do not include air receivers. An air receiver can

be purchased separately. Please consult our distributors. Use

Chart 2 as a guideline for sizing the air receiver.

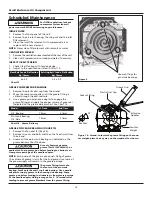

1. Make sure the piping is lined up without being strained

or twisted when assembling the piping for the scroll

compressor.

2. Appropriate expansion loops or bends should be installed

at the compressor to avoid stresses caused by changes in

hot and cold conditions.

3. Piping supports should be anchored separately from the

compressor to reduce noise and vibration.

4. Never use any piping smaller than the compressor

connection.

5. Use

fl exible hose to connect the outlet of the compressor

to the piping so that the vibration of the compressor

does not transfer to the piping.

SAFETY VALVES

The fl ow capacity of a safety valve should be equal to or

greater than the capacity of the compressor.

1. The pressure setting of the safety valve must not be

greater than the maximum working pressure of the air

receiver.

2. Safety valves should be placed ahead of any possible

blockage point in the system, i.e. shutoff valve.

3. Avoid connecting the safety valve with any tubing or

piping.

4. Manually operate the safety valve every six months to

avoid sticking or freezing.

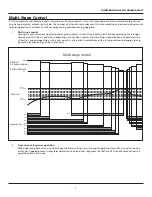

Model

10 HP

15 HP

20 HP

30 HP

40 HP

Air Receiver Minimum

Capacity (gallons)

30

60

60

110

160

Chart 2