5. Keep spare grinding wheels in dry places, protected from knocks or falls.

6. use only mPa standard spare grinding wheels no more than 4" in diameter.

Substandard wheels

might explode during use, putting the operator in serious danger.

7. never use a wheel that has been worn down to a diameter of 3" or less.

8. wheels must turn clockwise, as shown by the arrow on the fixed wheel guard.

9. Only use wheels that have an operating speed equal to or higher than the tool's operating speed

(6,300 rPm).

10. never tamper with the tool’s plug or power supply lead.

If necessary, have any repairs done by a

skilled technician.

11. after fitting, replacement wheels must turn freely.

Do not keep on using wheels that vibrate or have

become distorted.

12. Do not move the move the chain on with your left hand with the wheel in motion.

13. Do not stop the wheel with your hands or other objects

14. treat the chain teeth with caution when at work, they may cause deep cuts.

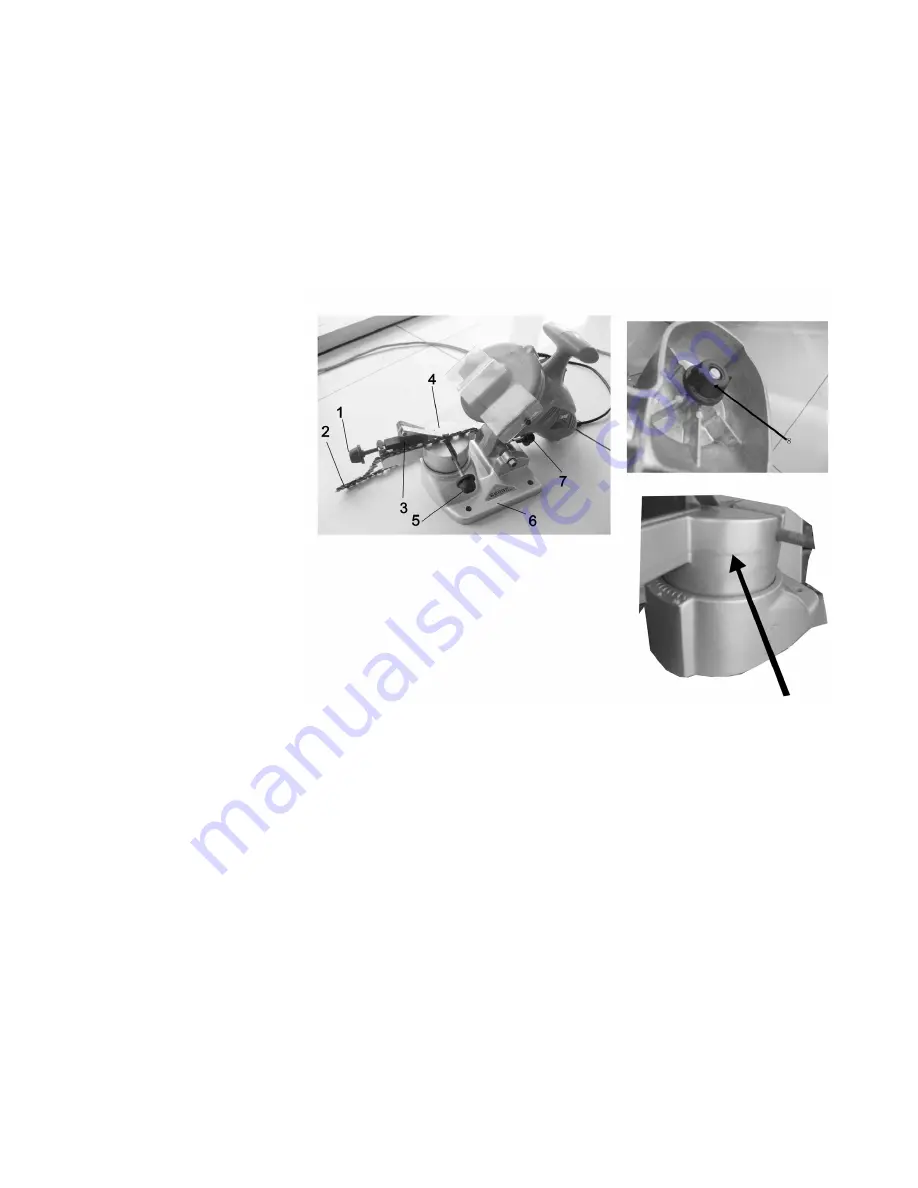

Changing thE whEEl

If the wheel wears beyond the permitted limit (more than 1") or is unbalanced, it must be

replaced. use only abrasive wheels compliant with the mPa standards, 4" in diameter and

guaranteed for the tool’s operating speed when not sharpening (6,300 rPm).

1. unplug the tool.

2. unscrew the m8 x 100 fixing bolt by using the 13 mm spanner (see fig. 1) to detach the whole unit

from the worktable (see fig. 2).

3. remove the safety guard (see fig. 3).

4. Insert the stopping bolt (see fig. 4) into the hole at the bottom of the unit to lock the spindle and

then unscrew the fixing bolt of the guard by using the 13 mm spanner (see fig. 5).

5. Put the new disk (see fig. 5) and then the top flange onto the spindle (see fig. 4), stop the spindle

by putting the bolt into the hole and tightening the nut by using the 13 mm spanner.

6. re-install the guard and tighten the m4 10 screw.

7. fix the whole unit onto the worktable and put the m8 100 screw into the connection hole and then

tighten the nut by using the 13 mm spanner (see fig.1).

for any technical questions, please call 1-800-665-8685

4

partS indEx

1. m6 adjust screw

2. saw chain

3. stop fade iron piece

4. Base

5. Push/pull piece

adjustment button

6. m6*65 adjust screw

7. m8 knob

8. m8 knob

9. chain bracket

8252165

8

9