1/2 in. Air Ratchet and Socket Set

9

Visit www.princessauto.com for more information

8395881

V 2.5

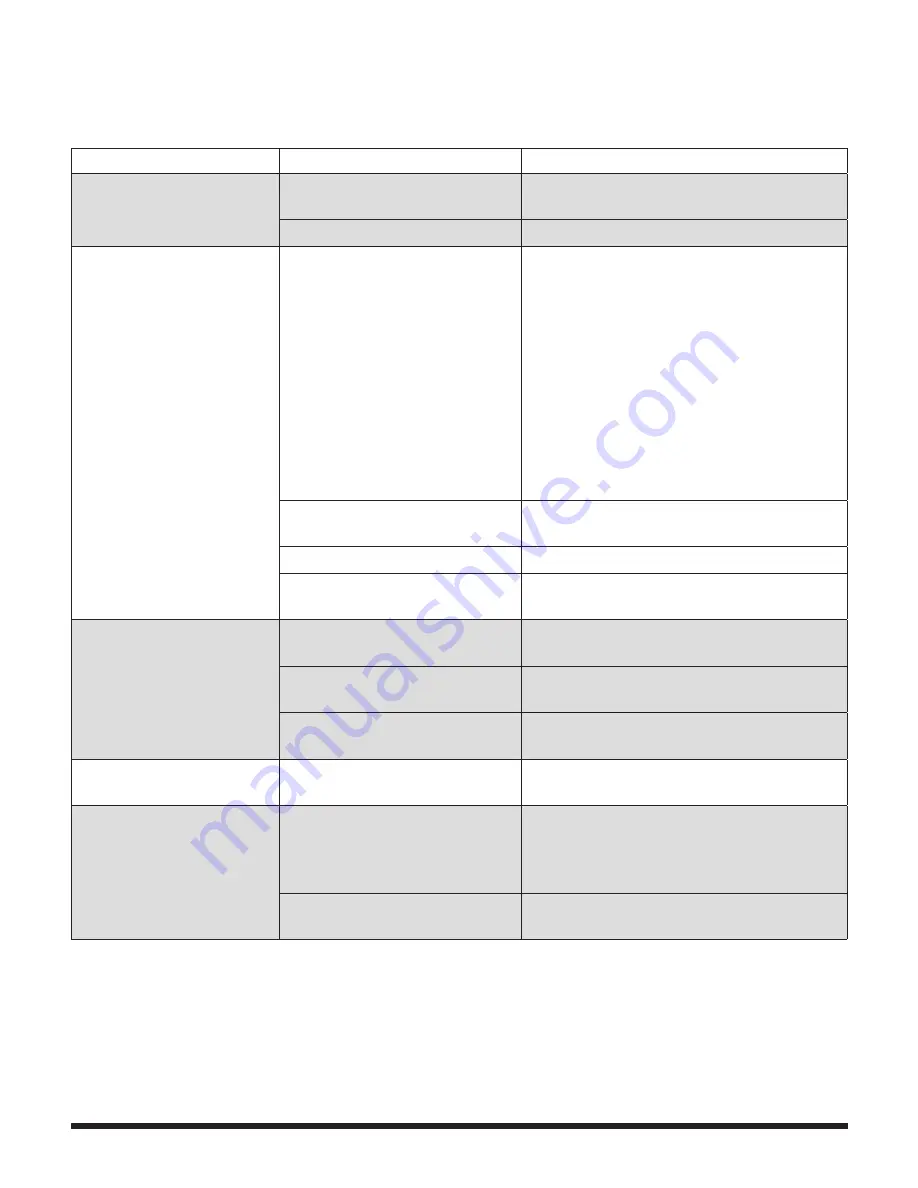

TROUBLESHOOTING

If the tool does not function properly or if it is missing parts, contact Princess Auto Ltd. for a solution. If unable to

do so, have a qualified technician service the tool.

Problem(s)

Possible cause(s)

Suggested solution(s)

Tool runs at normal speed

but loses power under load.

Motor parts worn.

Bring to Princess Auto Ltd. or a

qualified technician.

Lack of air tool oil.

Pour air tool oil into air inlet per instructions.

Tool runs slowly. Air flows

slightly from exhaust.

Motor parts jammed with

dirt particles.

OR

Air flow blocked by dirt.

Check air inlet filter for blockage.

Pour air tool oil into air inlet as per

instructions.

Operate tool in short bursts.

Disconnect air supply. Free motor by rotating

drive shank manually where applicable.

Repeat above as needed. If this fails, bring to

Princess Auto Ltd. or to a qualified technician.

Excessive air tool oil in tool.

Run tool under no load for short periods of

time until exhaust clears.

Buildup of shipping grease.

See Removing Packing Grease section.

Air flow regulator is in the closed

position

Open regulator to correct position

Tool will not run. Air flows

freely from exhaust.

O-rings throttle valve dislodged

from seat inlet valve.

Have a qualified technician replace the O-ring.

Damage or excessive wearing of

internal parts.

Bring to Princess Auto Ltd. or

a qualified technician.

Material buildup impeding

motor vanes.

Clean internal mechanism.

Tool will not shut off.

O-rings throttle valve dislodged

from seat inlet valve.

Bring to Princess Auto Ltd. or

a qualified technician.

Loss of power or

erratic performance.

Excessive drain on the air line.

Moisture or restriction in the air

hose. Incorrect size or type of

hose connectors.

Check the air supply. Ensure tool is connected

to a 3/8 in. I.D. or larger air hose with no

kinks or restrictions and that the fittings are

connected properly.

Air compressor has

insufficient flow.

Ensure tool is connected to a compressor with

a rated flow that matches the tool.