10 Installation Requirements

Part No. 27/20334

Installation Requirements - Page 10

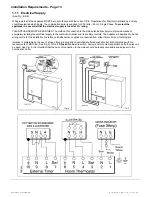

Frost Protection

The tank of hot water will provide frost protection. This is

purely for the protection of the appliance. If any other part of

the central heating system requires frost protection, an

external frost thermostat must be fitted in the usual manner,

refer to Fig. 9 for wiring.

1.6

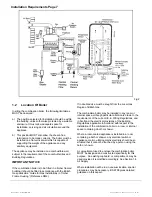

Mains Water Feed: Central Heating

A connection must be incorporated into the central heating

system to facilitate filling. There must be no direct connection

to the mains water supply, even through a non-return valve,

without the approval of the Local Water Authority.

PERMISSIBLE METHODS OF FILLING

Note:

The Puma combination boiler range is fitted with a

diverter valve design which has a manual operation lever to

aid filling. To ease filling of the pump manifold an air bleed

valve is fitted to the diverter and must be opened during filling

until water flows out. The valve should then be closed.

See Fig.13.

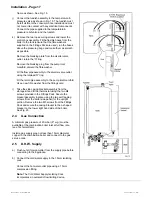

(1) DIRECT METHOD

(Fig. 5)

A detachable flexible hose is connected to a stop valve fitted

to an outlet on the service main. The other end of the hose is

connected to a second stop valve and a double check valve.

The double check valve is fitted to an inlet connection on the

central heating return pipe under the appliance. The hose

should be disconnected after filling. Where the mains pressure

is excessive a pressure reducing

valve shall be used to make filling easier. The following fittings

shall form a permanent part of the system and shall be fitted in

the order stated.

a) A stop valve complying with the requirements of BS

1010 Part 2, (the temporary hose from the draw off tap

shall be connected to this fitting).

b) Double check valve of an accepted type.

(2) BOOSTER PUMP METHOD

The system may be filled through a self contained unit

comprising a cistern, pressure booster pump and if

necessary, an automatic pressure-reducing valve or flow

restrictor.

The pressure booster pump must be capable of pressurising

the system to a minimum of 1.0 bar (14 p.s.i.) measured at the

appliance.

The cistern should be supplied through a temporary

connection from a service pipe or cold water distributing pipe.

The unit may remain permanently connected to the heating

system to provide limited water make-up.

Provisions for make up water

Provision should be made for replacing water loss from the

system by re-pressurisation of the system. See section on

Permissible Methods of Filling.

Reference should be made to British Gas Publications

"Material and Installation Specifications for Domestic Central

Heating and Hot Water".

1.7

Installation to an Existing Central

Heating System

The boilers are designed to operate on a sealed system only,

therefore if the existing system is of the open type it will have

to be modified to comply with BS 6798.

Before installing a new combination boiler to an existing

system flush out the old system with a recommended

descaling/flushing agent at least twice.

Also check pipework and renew any corroded pipework or

fittings. Valve glands must be re-packed or replaced wherever

necessary and any defective controls replaced.

1.8

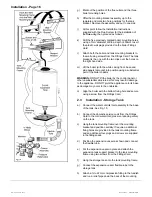

Hard Water Areas

If the area of installation is recognised as a hard water area,

(above 200 p.p.m.) it is essential that a suitable water

treatment device of an electronic, magnetic or galvanic type be

installed in the mains water supply.

To assess water hardness, immerse the test strip supplied, for

about one second in a water sample (NOT IN RUNNING

WATER) so as to moisten all the zones.

Inspect the strip after 1-2 minutes, check the zones, if two or

more zones have changed colour the hardness of the water is

above 200 p.p.m. and a water treatment device will be

required.

1.9

Pump Performance Curve

The circulating pump fitted within the appliance should be

capable of satisfying most system requirements. Fig. 6

indicates the amount of pump head available for the system.

The boiler resistance is already taken into account in this

curve.

Содержание Puma Flowsure+

Страница 5: ...Part No 27 20334 Introduction 5 Introduction Page 5 ...

Страница 28: ...28 Routine Maintenance Part No 27 20334 Routine Maintenance Page 28 ...

Страница 30: ...30 Routine Maintenance Part No 27 20334 Routine Maintenance Page 30 ...

Страница 34: ...34 Component Replacement Part No 27 20334 Component Replacement Page 34 ...

Страница 42: ...42 Control Flow Sequence Part No 27 20334 8 Control Flow Sequence Page 42 ...

Страница 43: ...Part No 27 20334 Functional Flow 43 9 Functional Flow Page 43 ...

Страница 44: ...44 Pictorial Wiring Diagram Part No 27 20334 10 Pictorial Wiring Diagram Page 44 ...

Страница 45: ...Part No 27 20334 Electrical Diagram 45 11 Electrical Diagram Page 45 ...

Страница 47: ...Part No 27 20334 Short List of Spares 47 Short List of Spares Page 47 Back page ...